DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer multi spring seal Supply for aviation

- Dms Seals insists on providing sincere services to seek common development with customers.

1. DMS Seal Manufacturer will be scrutinized by professional workers for its workmanship. Seaming and Stitching quality will be checked more carefully, especially for the irregular stitch density, crooked stitches, skipped stitches, exposed seam grin, unwanted pleat, and cracked seam.

2. DMS Seal Manufacturer is designed based on considerations for human physical structure. The design takes into account body weight distribution, physiological structure development, as well as the anatomy and movement of the foot.

3. Before delivery, DMS Seal Manufacturer has to undergo a wide range of tests. It is strictly tested in terms of the strength of its materials, statics&dynamics performance, resistance to vibrations&fatigue, etc.

4. DMS Seal Manufacturer is analyzed and inspected on the basis of strict quality requirements. It has passed the inspection of appearance, physical properties, finishing properties, colorfastness, etc.

5. The fabrics of DMS Seal Manufacturer face the necessary finishing processes. These processes mainly include bleaching, dyeing, printing, and heat setting.

6. The product has the advantage of water repellency. Its seam sealing and coating create a barrier to block the water.

7. The product is able to control multiple components to work at the same time thanks to its fast computing capability.

8. The product is resistant to fire. It is able to ensure that its structural integrity remains while shielding from heat.

9. Since its establishment, DMS Seal Manufacturer has won the recognition of multi spring seal .

10. Dms Seals Technology Co.,limited consistantly summarizes multi spring seal ' developing experience, and improve the function of spring loaded oil seal continuously.

11. Dms Seals Technology Co.,limited's technical security and R&D capabilities are first class in the industry.

12. Different raw materials of multi spring seal such as are available during customization.

13. Identifying the competitive advantage for itself and sustaining it is at the heart of Dms Seals Technology Co.,limited.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

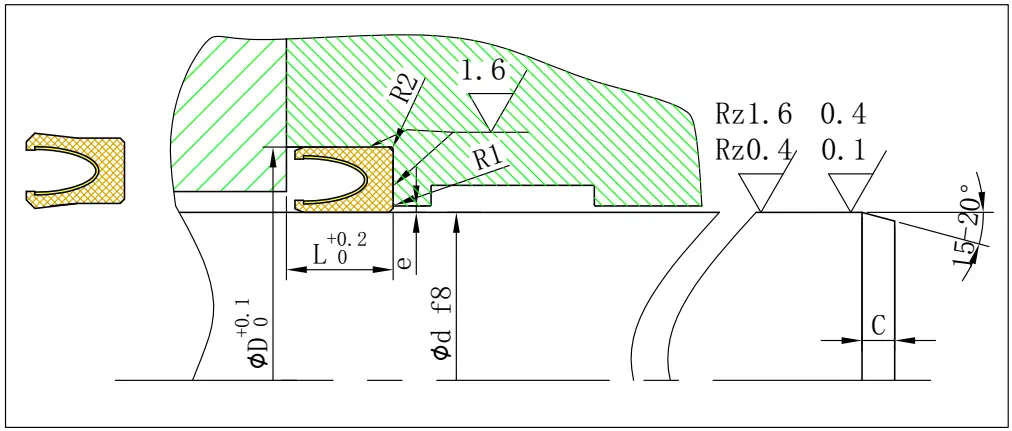

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is widely known as a reliable and professional multi spring seal manufacturer. Dms Seals Technology Co.,limited enjoys a high reputation as a professional spring loaded oil seal manufacturer. Dms Seals Technology Co.,limited is an internationally competitive mechanical seal arrangement manufacturer. Dms Seals Technology Co.,limited provides customers with customized shaft seals for dynamic applications and project solutions. In the past few years, DMS Seal Manufacturer has promoted into a major brand.

2. Our carbon teflon seals is a product with a high cost-performance ratio and appreciates exceptional quality. Dms Seals Technology Co.,limited is technologically strong with advanced production equipment and experienced technician. The quality of the unbalanced mechanical seal is totally guaranteed. mechanical shaft seals springs has won the praise of customers with its highest quality.

3. DMS Seal Manufacturer seeks common ground while reserving differences with our customers. Contact us! The conformable atmosphere and profound of DMS Seal Manufacturer motivate staff to work harder. Contact us! DMS Seal Manufacturer hopes to be a professional brand in the global market. Contact us! We hope that we can steer the development of rod end seals market. Contact us!

DMS Seal Manufacturer multi spring seal Supply for aviation

multi spring seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US