DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic seals for pressure work and sliding high speed occasions

- With a sound service system, Dms Seals is committed to sincerely providing excellent services including pre-sale, in-sale, and after-sale. We meet users' needs and improve the user experience.

1. In the unpredictable waves of evolving regulatory requirements for DMS Seal Manufacturer hydraulic seals , the factory collaborates closely with reliable quality authentication institutes to guarantee its quality meets the gifts and crafts standards.

2. For the development and manufacture of DMS Seal Manufacturer hydraulic seals , many factors such as the safety of metallic elements have been considered from a quality assurance perspective in order to meet the basic requirements of the storage battery industry.

3. The production process of DMS Seal Manufacturer has been greatly improved by our professionals. They carry out a complete printing management system to minimize the impact on the environment.

4. The core issues relating to the design of DMS Seal Manufacturer hydraulic seals include many aspects such as health risk related to emerging parameters (chemical and microbiological), NOM removal, advanced treatment processes for new micro-pollutants removal, etc.

5. The product is durable and anti-aging. It can endure longstanding and monotonous repeated mechanical operation without failure and malfunction.

6. The product is not prone to deform. The tempering process has eliminated the internal stress of work blank to prevent or reduce any deformation.

7. The product can work in extreme conditions. It performs stably under high and low temperature, as well as in a condition where is full of dust and radiation.

8. The product can help clients improve their competitiveness in the market, bringing wider market application.

9. The product finds its wide application in the industry.

10. This product is at feasible market prices to meet the specific requirements of customers.

11. As we continue to make product improvement to better satisfy customers, this product will be more welcomed by the market in the future.

12. The product has won the trust of its customers and has wider application in the coming future.

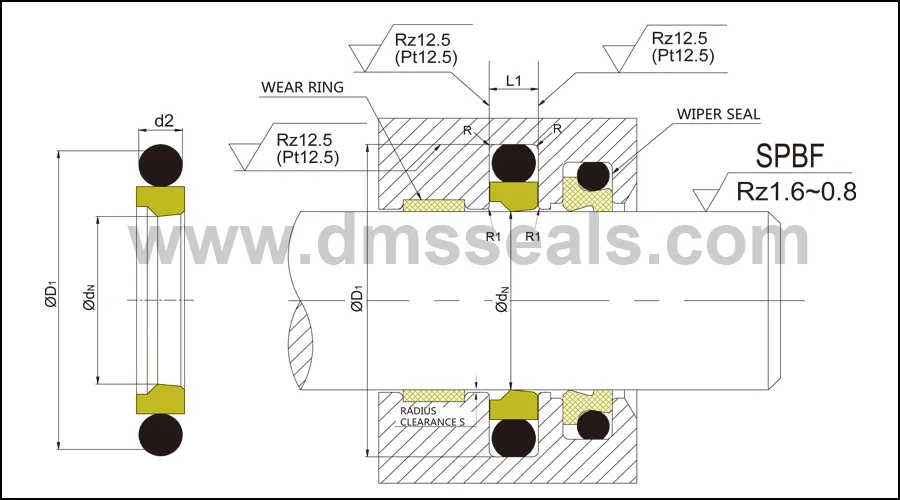

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation. Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

22 25 25 | 32.7 32.3 35.7 | 4.2 3.2 4.2 | GSJ22*32.7*4.2 GSJ25*32.3*3.2 GSJ25*35.7*4.2 | 26.57*3.53 26.64*2.62 29.74*3.53 |

28 30 32 | 38.7 40.7 42.7 | 4.2 4.2 4.2 | GSJ28*38.7*4.2 GSJ30*40.7*4.2 GSJ32*42.7*4.2 | 31.34*3.53 34.52*3.53 36.09*3.53 |

35 36 38 | 45.7 46.7 53.1 | 4.2 4.2 6.3 | GSJ35*45.7*4.2 GSJ36*46.7*4.2 GSJ38*53.1*6.3 | 37.69*3.53 40.87*3.53 43.82*5.33 |

40 40 42 | 50.7 55.1 57.1 | 4.2 6.3 6.3 | GSJ40*50.7*4.2 GSJ40*55.1*6.3 GSJ42*57.1*6.3 | 44.04*3.53 43.82*5.33 46.99*5.33 |

45 45 50 | 55.7 60.1 60.7 | 4.2 6.3 4.2 | GSJ45*55.7*4.2 GSJ45*60.1*6.3 GSJ50*60.7*4.2 | 47.22*3.53 50.17*5.33 53.57*3.53 |

50 55 56 | 65.1 70.1 66.7 | 6.3 6.3 4.2 | GSJ50*65.1*6.3 GSJ55*70.1*6.3 GSJ56*66.7*4.2 | 56.52*5.33 59.69*5.33 59.92*3.53 |

56 56 60 | 71.1 76.5 75.1 | 6.3 8.1 6.3 | GSJ56*71.1*6.3 GSJ56*76.5*8.1 GSJ60*75.1*6.3 | 59.69*5.33 62.87*6.99 66.04*5.33 |

Company Features

1. Dms Seals Technology Co.,limited has a solid hydraulic seals manufacturing capability. Dms Seals Technology Co.,limited is a nationwide high-tech enterprise and a world-famous hyd cylinder seal kit producer. Dms Seals Technology Co.,limited, focusing on the production and research and development of hydraulic cylinder piston seal leakage , has a good reputation at home and abroad.

2. The application of high technology is good for the production of hydraulic packing kits . The hydraulic seals ppt is made by highly proficient technology. More customers speak highly of the quality of rod seal catalogue made by DMS Seal Manufacturer.

3. Dms Seals Technology Co.,limited sincerely hopes that our customers will succeed in business transactions. Inquiry! Each of the details of rubber seals for fluid and hydraulic systems is emphasized by Dms Seals Technology Co.,limited for higher quality. Inquiry! In order to become a leader in the industry, DMS Seal Manufacturer has been doing its best to serve customers. Inquiry! DMS Seal Manufacturer aims to cooperate with customers to develop a higher quality on competitive products. Inquiry! Dms Seals Technology Co.,limited will tap into the our whole strength to provide you with the best. Inquiry!

DMS Seal Manufacturer hydraulic seals for pressure work and sliding high speed occasions

hydraulic seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US