DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic rod seal installer factory for pneumatic equipment

1. DMS Seal Manufacturer is made with the appropriate fabric according to the popular trend, quality, performance, price, and applicability.

2. Quality control is carried out at the initial stage of DMS Seal Manufacturer production to ensure the qualified rate of raw material inspection in textile industry.

3. The materials used for DMS Seal Manufacturer have been tested. The testing procedures include tensile testing, toughness or brittleness testing, hardness testing, infiltrate testing and testing through radiations.

4. DMS Seal Manufacturer is professionally developed. Its development work is carried out by the expert R&D staff who have the knowledge of mechanical design automation and intelligent manufacturing technology, as well as the ability in solving practical engineering problems.

5. The design of DMS Seal Manufacturer conforms to specific heavy-duty usage requirements. It is designed with characteristics of enhanced mechanical structure, less energy consumption parts, and durable components.

6. The product is able to maintain its color. It is not susceptible to cosmetics that contain zinc oxide, titanium dioxide, ferric oxide, and calamine.

7. The product is characterized by its nearly zero porosity. During its production, it has gone through the enameling process which diminishes the porous problem.

8. The product is not easy to crack and warp. It is able to expand and contract flexibly to stand up the extremely high temperatures.

9. Prior to the development and design of new products, DMS Seal Manufacturer carefully analyzed customer needs.

10. Dms Seals Technology Co.,limited has a large-scale production and strong economic strength.

11. The product brings huge economic benefits to customers.

12. The practical applications of the product is increasingly prominent.

13. Aided by our experienced team, the customer service of DMS Seal Manufacturer is highly recommended by our customers.

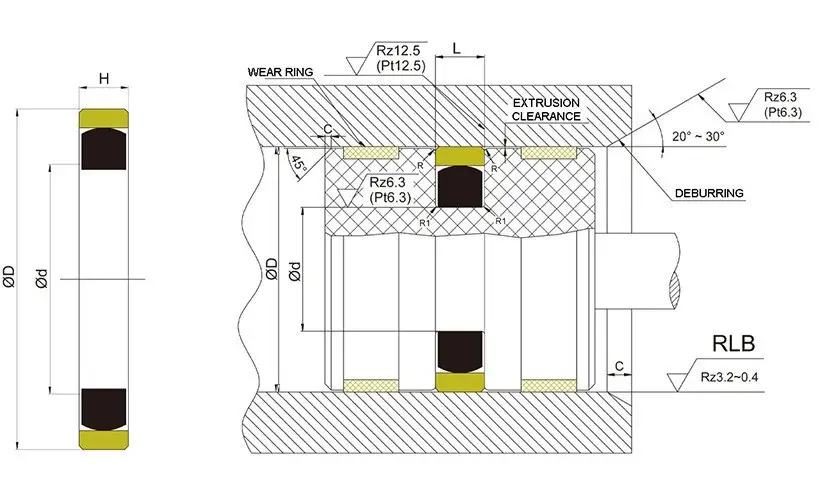

Bore Diameter | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | |||

D H8 | d h8 | L1+0.2 | R1 | 16MPa | 26MPa | 32MPa | 40MPa |

55.0-149.9 | D-10.0 | 10.0 | 0.4 | 0.60 | 0.50 | 0.40 | 0.40 |

150.0-244.9 | D-12.5 | 12.5 | 0.4 | 0.75 | 0.65 | 0.55 | 0.50 |

245.0-500.0 | D-15.0 | 15.0 | 0.8 | 0.75 | 0.65 | 0.55 | 0.50 |

500.1-760.0 | D-17.5 | 17.5 | 1.2 | 0.75 | 0.65 | 0.55 | 0.50 |

760.1-999.9 | D-20.0 | 20.0 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

≧1000 | D-20.0 | 20.5 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

Application and properties

Applied to the hydraulic cylinder of heavy machinery and metallurgical equipment. Pressure resistance and corrosion resistance are strong, good thermal conductivity,structure anti-distortion, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+100℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. |

D H8 | d h8 | L+0.2 | |

55 | 40 | 10 | GSF-W55*40*10 |

80 | 60 | 10 | GSF-W80*60*10 |

110 | 90 | 10 | GSF-W110*90*10 |

130 | 110 | 10 | GSF-W130*110*10 |

160 | 135 | 12.5 | GSF-W160*135*12.5 |

180 | 155 | 12.5 | GSF-W180*155*12.5 |

200 | 175 | 12.5 | GSF-W200*175*12.5 |

215 | 190 | 12.5 | GSF-W215*190*12.5 |

230 | 205 | 12.5 | GSF-W230*205*12.5 |

Company Features

1. Dms Seals Technology Co.,limited is widely recognized by customers at home and abroad. Dms Seals Technology Co.,limited has its own advantage to produce hydraulic rod seal installer with high quality. With highly advanced equipment, DMS Seal Manufacturer has been the at leading position of the air cylinder piston seals market. DMS Seal Manufacturer has dominated the leading place in polyurethane hydraulic seals market. Dms Seals Technology Co.,limited is a well-known expert for hydraulic piston seals suppliers in China.

2. Dms Seals Technology Co.,limited has a outstanding ability in scientific research and development. Through proficiently experienced technology, hyd cylinder seal kit is made to be of excellent quality. Dms Seals Technology Co.,limited has accumulated a wealth of technical experience. Dms Seals Technology Co.,limited prioritizes R&D investment based on extensive research on emerging technology trends and customer challenges. hydraulic cylinder packing replacement has mature product structure and production process.

3. We invest in ongoing training and development by integrating the people dimension into business strategies, increasing the effectiveness of delivery and enhancing our employees’ skills, abilities, and aspirations. We take immense pride in providing the best service. We work hard to ensure that you are well taken care of when you choose us. Your satisfaction is our main priority and we strive to prove that every day. Welcome to visit our factory! Our firm bears societal responsibilities. Our efforts in attaining exactly the identical product possessions with less raw material contribute to not simply cost savings but greater CO² footprints and a massive decrease in waste.

DMS Seal Manufacturer hydraulic rod seal installer factory for pneumatic equipment

hydraulic rod seal installer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US