DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic pump seals suppliers Supply to high and low speed

- provides customers with a full range of services to meet the individual needs of different customers.

1. The modernized production mode accelerates DMS Seal Manufacturer production process.

2. hydraulic pump seals suppliers is known by users throughout the world.

3. The design of DMS Seal Manufacturer can be customized to meet various target markets.

4. The product is designed to withstand extreme temperatures. It is 100% waterproof, compliant with International Fire Rating, UV and fungal treated with excellent stretch and recovery properties.

5. This product is durable. The anodized finish, as an integral part of its substrate, provides excellent wear and abrasion resistance with minimal maintenance.

6. The reflectivity of this product is satisfying. The screen's multiple layers of diffusion material negate the washout effects of ambient light for sharp image clarity.

7. It is highly competitive and qualified in the market.

8. It has a good application prospect and value.

9. This product fulfills consumer demands with competitive advantages.

10. This product is becoming a must for the domestic and international market.

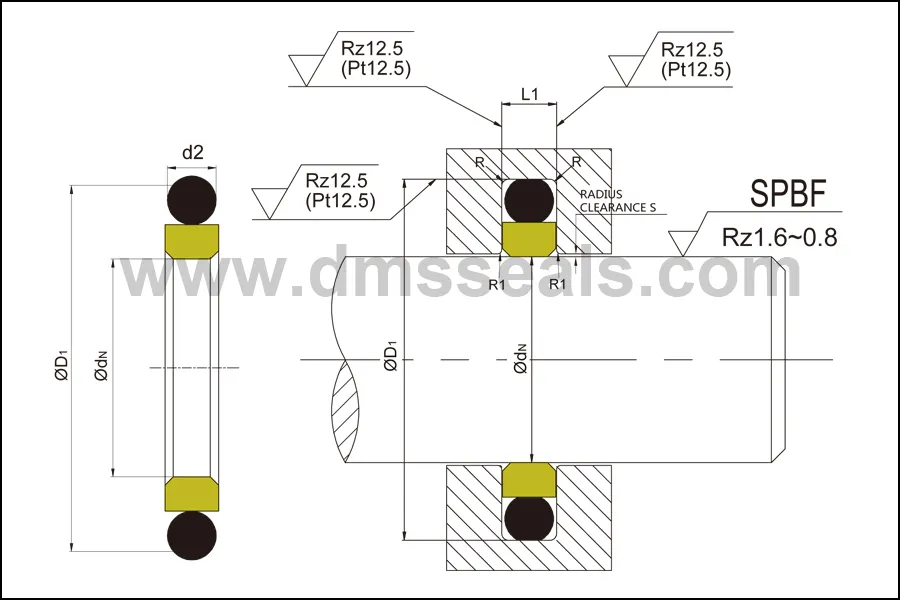

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in themedium with oil spots.

Meet the standard of GB/T 15242.3.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSI20*27.3*3.2 GSI20*30.7*4.2 GSI22*29.3*3.2 | 21.89*2.62 25.0*3.53 25.07*2.62 |

22 24 25 | 32.7 31.3 32.3 | 4.2 3.2 3.2 | GSI22*32.7*4.2 GSI24*31.3*3.2 GSI25*32.3*3.2 | 26.57*3.53 26.64*2.62 28.24*2.62 |

25 26 28 | 35.7 36.7 35.3 | 4.2 4.2 3.2 | GSI25*35.7*4.2 GSI26*36.7*4.2 GSI28*35.3*3.2 | 29.74*3.53 29.74*3.53 29.82*2.62 |

28 30 30 | 38.7 37.3 40.7 | 4.2 3.2 4.2 | GSI28*38.7*4.2 GSI30*37.3*3.2 GSI30*40.7*4.2 | 32.92*3.53 32.99*2.62 34.52*3.53 |

32 32 35 | 39.3 42.7 42.3 | 3.2 4.2 3.2 | GSI32*39.3*3.2 GSI32*42.7*4.2 GSI35*42.3*3.2 | 34.59*2.62 36.09*3.53 37.77*2.62 |

35 36 36 | 45.7 43.3 46.7 | 4.2 3.2 4.2 | GSI35*45.7*4.2 GSI36*43.3*3.2 GSI36*46.7*4.2 | 37.69*3.53 39.34*2.62 40.87*3.53 |

38 38 40 | 48.7 53.1 50.7 | 4.2 6.3 4.2 | GSI38*48.7*4.2 GSI38*53.1*6.3 GSI40*50.7*4.2 | 40.87*3.53 43.82*5.33 44.04*3.53 |

Company Features

1. With special advantages, DMS Seal Manufacturer is outstanding in the hydraulic pump seals suppliers industry. DMS Seal Manufacturer has a full set of management system and sound technology methods. DMS Seal Manufacturer has been exporting its high quality packing rod seals for years. Dms Seals Technology Co.,limited is a large-scale and professional manufacturer of cylinder rod seal .

2. Our employees share the same values and enforce the same standards of quality, efficiency, and customer satisfaction on which we have built our reputation. Our company has strong teams. Thanks to their extensive knowledge and expertise, our company can offer an integrated solution that most other manufacturers can’t. Our company has kept growing year by year in the volume of exporting products. We have exported most of our products to the United States, Australia, Germany, and some Asia countries. We have gained a considerable market share in overseas markets after years of active market exploration. We have built strong customer bases in North America, Australia, and Southeast Asia. Our factory operates in conformity with the industry standard, being supervised by the qualified structural and technological department. And the introduction of advanced equipment allows us to manufacture the most optimal products.

3. Focusing on cultivating high-level and innovative talents is the assurance for the improvement of DMS Seal Manufacturer. Ask! Our resolve is to build DMS Seal Manufacturer into a leading hydraulic cylinder shaft seals manufacturer. Ask! Reform and Innovation are what Dms Seals Technology Co.,limited has been insisted. Ask!

DMS Seal Manufacturer hydraulic pump seals suppliers Supply to high and low speed

hydraulic pump seals suppliers

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US