DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer High-quality rotary lip seal application for business for construction machinery

1. The production of DMS Seal Manufacturer is in compliance with the international industry standards. We have developed solutions of the sealing of special working condition

2. With strong capital and independent R&D team, Dms Seals Technology Co.,limited is a dynamic and innovative team. The high pressure seals have strong wear resistance to hard conditions

3. rotary lip seal application is considered as the most promising to . We can support OEM and ODM

4. rotary lip seal application has the advantages of and so on, which has huge fact significance as well as spread worthiness. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

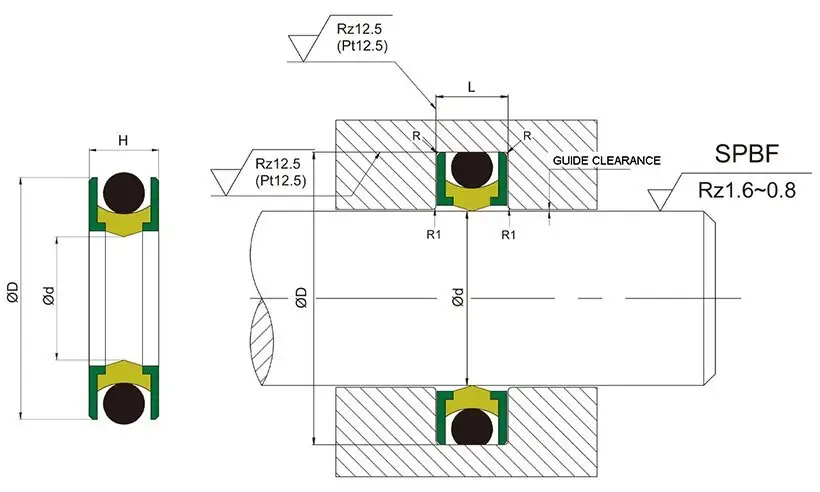

Rod Diameter | Groove Diameter | Seal Width | Groove Width | Guide Clearance S max | |

d e8 | D H9 | H | L | 0-10MPa | 15-36MPa |

50-79 | d+10.0 | 4.5 | 5.0 | 0.40-0.30 | 0.30-0.25 |

80-109 | d+13.8 | 7.0 | 7.5 | 0.45-0.35 | 0.35-0.30 |

110-299 | d+20.0 | 9.5 | 10.0 | 0.55-0.45 | 0.45-0.35 |

300-600 | d+24.0 | 12.5 | 13.0 | 0.60-0.55 | 0.55-0.45 |

Application and properties

Applicable to construction machinery, construction machinery and automotive equipment and other industrial fields. Consisting of a sealing ring, a O-Ring and two retaining rings, the sealing surface profile is specially designed to accommodate high pressure and low speed, the design of the back of the seal ring increases the contact surface and prevents rotation with the rod or shaft. Low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-36MPa | -36℃+100℃ | 0.5 m/s | hydraulic oil, flame retardant liquid, water and others |

d e8 | D H9 | H | L | e | Order No. |

50 | 60 | 4.5 | 5 | 7 | OI50*60*4.5 |

65 | 75 | 4.5 | 5 | 7 | OI65*75*4.5 |

80 | 93.8 | 7.0 | 7.5 | 7 | OI80*93.8*7 |

95 | 108.8 | 7.0 | 7.5 | 7 | OI95*108.8*7 |

115 | 135 | 9.5 | 10 | 10 | OI115*135*9.5 |

130 | 150 | 9.5 | 10 | 10 | OI130*150*9.5 |

160 | 180 | 9.5 | 10 | 10 | OI160*180*9.5 |

190 | 210 | 9.5 | 10 | 10 | OI190*210*9.5 |

225 | 245 | 9.5 | 10 | 10 | OI225*245*9.5 |

Company Features

1. We have a design team good at flexible designs. Combining their years of experience and expertise, they can design new products that are adaptable to customers' requirements.

2. Providing the highest quality rotary lip seal application has always been DMS Seal Manufacturer efforts to do. Get more info!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US