DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer High-quality piston seal material manufacturer for pneumatic equipment

1. The manufacturing process of DMS Seal Manufacturer is sustainable. This includes prioritizing the responsible sourcing of ingredients, implementing earth-friendly manufacturing method, and experimenting with inventive recycling programs.

2. DMS Seal Manufacturer is professionally designed. It is created by our CAD designers who have the technology and expertise to create jewelry ideas rendered in three dimensions.

3. The production of DMS Seal Manufacturer involves these processes: material preparation, CNC milling, CNC turning, grinding, wire electro-erosion, adjusting, CAD cam programming, mechanical measuring and control, and welding.

4. Every batch of DMS Seal Manufacturer is tested to verify it meets strict quality requirements. These tests include chemical resistance test, aging test, low-temperature performance test, and abrasion resistance test.

5. The manufacturing process of DMS Seal Manufacturer piston seal material involves coagulating the field latex with acid and passing the coagulated latex through cutting machines and a series of creping rollers.

6. The product stands out for its high energy efficiency. Adopting low energy consumption technology, it only consumes little energy in operation.

7. This product has no major defects, i.e. dangerous or unsafe environment or non-compliance, including sharp points or edges, loose stitches left on clothing, loose nails or lack of suffocation warning labels.

8. The product is known for its remarkable energy efficiency. It can maximize its energy utilization to adapt to different working modes.

9. Our QC team are strict with quality checking for piston seal material to ensure high quality.

10. As a famous brand at home and abroad, DMS Seal Manufacturer always supply highest quality piston seal material for customers.

11. DMS Seal Manufacturer team is positive and super-strong cohesive.

12. DMS Seal Manufacturer has comprehensive expertise on piston seal material .

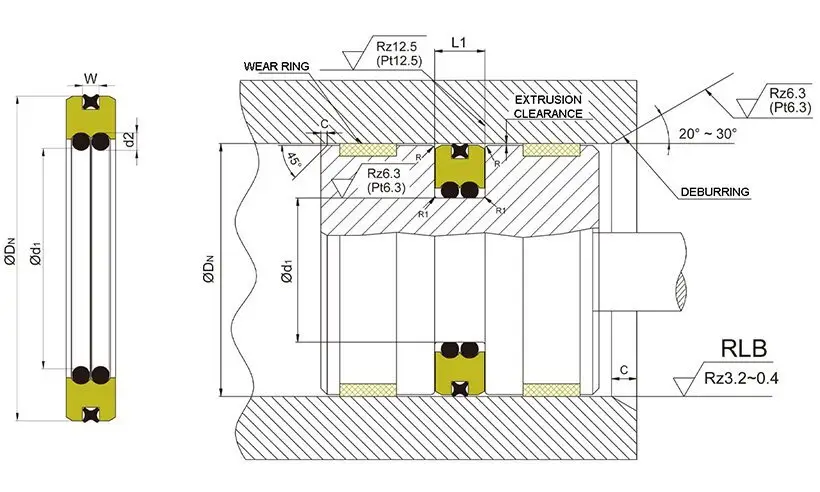

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

40 - 79.9 | 25 - 140 | DN - 10.0 | 6.3 | 0.6 | 0.3 | 0.2 | 0.15 | 2.62 | 1.78 |

80 - 132.9 | 50 - 250 | DN - 13.0 | 8.3 | 1.0 | 0.4 | 0.3 | 0.15 | 3.53 | 2.62 |

133 - 252.9 | 100 - 480 | DN - 18.0 | 12.3 | 1.3 | 0.4 | 0.3 | 0.20 | 5.33 | 3.53 |

463 - 700 | 425 - 700 | DN - 31.0 | 16.3 | 1.8 | 0.5 | 0.4 | 0.30 | 7.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Available for piston accumulator, clamping cylinder and positioning cylinder, especially recommended for heavy duty and large diameter applications. Double safety with low friction and high elasticity, Low gas permeability, excellent sliding performance in high pressure applications, no crawling phenomenon, simple groove structure, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+200℃ | 3 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

40 | 30 | 6.3 | DAQ2-40*30*6.3 | 29.82*2.62 |

48 | 38 | 6.3 | DAQ2-48*38*6.3 | 37.77*2.62 |

55 | 45 | 6.3 | DAQ2-55*45*6.3 | 44.12*2.62 |

65 | 55 | 6.3 | DAQ2-65*55*6.3 | 53.64*2.62 |

80 | 67 | 8.3 | DAQ2-80*67*8.3 | 66.27*3.53 |

95 | 82 | 8.3 | DAQ2-95*82*8.3 | 78.97*3.53 |

110 | 97 | 8.3 | DAQ2-110*97*8.3 | 94.84*3.53 |

125 | 112 | 8.3 | DAQ2-125*112*8.3 | 110.72*3.53 |

140 | 122 | 12.3 | DAQ2-140*122*12.3 | 120.02*5.33 |

Company Features

1. Dms Seals Technology Co.,limited is a Chinese manufacturer of . Through tireless efforts, our reputation has been gradually and profoundly built and strengthened. With decades of experience in the manufacturing of , Dms Seals Technology Co.,limited has been considered as a highly qualified manufacturer in the industry. As an excellent company embarking on the design and production of , Dms Seals Technology Co.,limited has become a professional manufacturer and supplier.

2. piston seal material is made by advanced technology and has high quality and won the favor of customers. Consistent technical invention retains DMS Seal Manufacturer at the top position in the industry. Keeping absorbing in the hydraulic cylinder shaft seals manufacturing technology keeps DMS Seal Manufacturer competitive in the industry.

3. We listen to our clients and put their needs first. We work creatively to achieve tangible benefits and find viable solutions to client issues. We attach importance to environmental protection. We will try hard to cut carbon footprint during production and reasonably handle and control production wastes. We bear social responsibilities. We place the highest requirements on our actions both within our sphere of influence and in all of our supply chains.

DMS Seal Manufacturer High-quality piston seal material manufacturer for pneumatic equipment

piston seal material

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US