DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer double mechanical seal centrifugal pump o ring

1. DMS Seal Manufacturer has gone through some important production stages. They cover the preparation of raw materials, parts machining, plating and anodizing, assembly, and testing. DMS Seals' production equipment and test equipment are on the leading level in the industry

2. It demonstrates the ultimate combination of craftsmanship and sophistication, designed to ensure a high quality sleep quality experience. DMS Seal manufacturer is a technology enterprise which specialized in the R&D and production of seals

3. The product has the characteristics of long service life, excellent performance and stable performance. The high pressure seals have strong wear resistance to hard conditions

4. To ensure durability, our highly skilled QC professionals strictly inspect the products. DMS o-ring seal has advanced machines and equipment for its production

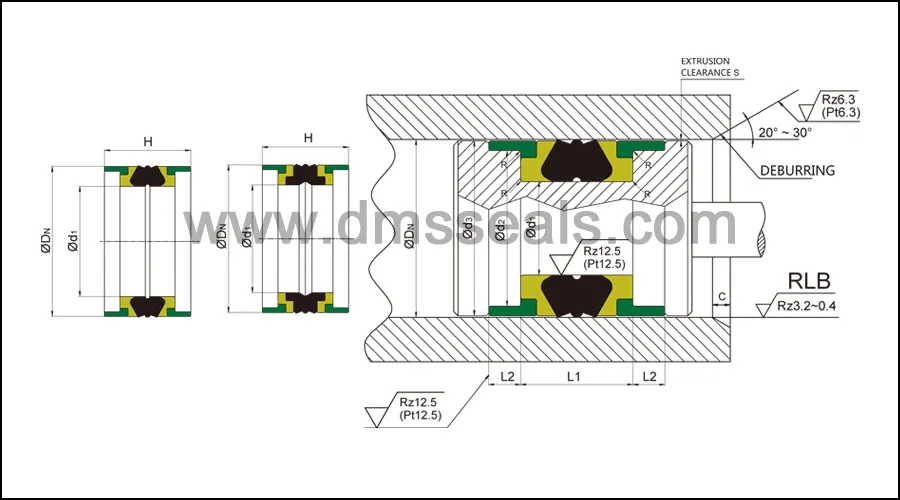

1. Installation Recommendation

2. Application and properties

DBM/TPM is a double acting sealing and guiding element, Consisting of an elastomer, two back-up rings and two guide rings. Dynamic and static properties of the elastomer play a good sealing role, The back-up ring prevents the elastomer from being squeezed into the sealing gap, the function of the guide ring is to guide the piston in the cylinder and absorb the radial force. The sealing is mainly used for piston and hydraulic cylinder, such as bulldozers, excavators, loaders, hydraulic gates and agricultural machinery.

3. Standard materials

Guide ring: filled PTFE / PA

Back-up ring: TPU polymer

Elastomer: NBR

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-35MPa | -30℃ +120℃ | 0.5 m/s | petroleum base hydraulic oil,nonflammable hydraulic oil, environmental protection hydraulic oil |

5. Installation Dimensions

Cylinder Dia. | Groove Size | Order No. | ||||

DN H9 | d1 | L1 +0.2 | d2 h9 | d3 h11 | L2 +0.1 | |

22 25 | 11 13 15 | 13.5 13.5 12 | 17 19 21 | 19 21 23 | 2.1 2.1 4 | TPM20*11*13.5*2.1 TPM22*13*13.5*2.1 TPM25*15*12*4 |

25 25 25 | 15 15 16 | 12.5 16.4 13.5 | 22 21.45 22 | 24 23.5 24 | 4 6.35 2.1 | TPM25*15*12.5*4 TPM25*15*16.4*6.35 TPM25*16*13.5*2.1 |

28 30 30 | 19 17 21 | 13.5 15.4 13.5 | 25 26.5 27 | 27 28.5 29 | 2.1 6.35 2.1 | TPM28*19*13.5*2.1 TPM30*17*15.4*6.35 TPM30*21*13.5*2.1 |

32 35 | 22 22 25 | 15.5 16.4 15.5 | 28 28.5 31 | 31 30.5 34 | 2.6 6.35 2.6 | TPM32*22*15.5*2.6 TPM32*22*16.4*6.35 TPM35*25*15.5*2.6 |

35 40 40 | 25 24 26 | 16.4 18.4 15.5 | 31.4 35.4 36 | 33.5 38.5 39 | 6.35 6.35 2.6 | TPM35*25*16.4*6.35 TPM40*24*18.4*6.35 TPM40*26*15.5*2.6 |

40 40 40 | 30 30 30 | 12.5 12.5 16.4 | 36 37 35.4 | 38 39 38.5 | 4 4 6.35 | TPM40*30*12.5*4 TPM40*30*12.5*4 TPM40*30*16.4*6.35 |

42 45 45 | 28 29 31 | 15.5 18.4 15.5 | 38 40.4 41 | 41 43.5 44 | 2.6 6.35 2.6 | TPM42*28*15.5*2.6 TPM45*29*18.4*6.35 TPM45*31*15.5*2.6 |

45 50 50 | 35 34 34 | 16.4 18.4 20.5 | 40.4 45.4 46 | 43.5 48.5 49 | 6.35 6.35 3.1 | TPM45*35*16.4*6.35 TPM50*34*18.4*6.35 TPM50*34*20.5*3.1 |

55 55 56 | 39 39 40 | 18.4 20.5 20.5 | 50.36 51 52 | 53.5 54 55 | 6.35 3.1 3.1 | TPM55*39*18.4*6.35 TPM55*39*20.5*3.1 TPM56*40*20.5*3.1 |

60 60 63 | 44 44 47 | 18.4 20.5 18.4 | 55.4 56 58.4 | 58.5 59 61.5 | 6.35 3.1 6.35 | TPM60*44*18.4*6.35 TPM60*44*20.5*3.1 TPM63*47*18.4*6.35 |

63 63 65 | 47 47 49 | 19.4 20.5 20.5 | 58.4 59 61 | 61.5 62 64 | 6.35 3.1 3.1 | TPM63*47*19.4*6.35 TPM63*47*20.5*3.1 TPM65*49*20.5*3.1 |

65 70 70 | 50 50 54 | 18.4 22.4 20.5 | 60.4 64.2 66 | 63.5 68.3 69 | 6.35 6.35 3.1 | TPM65*50*18.4*6.35 TPM70*50*22.4*6.35 TPM70*54*20.5*3.1 |

Company Features

1. Dms Seals Technology Co.,limited gives enthusiasm for design and manufacturing double mechanical seal centrifugal pump . We offer the most reliable products and dedicated services that our customers deserve. Dms Seals Technology Co.,limited is technologically strong with advanced production equipment and experienced technician.

2. DMS Seal Manufacturer actively presents high-end abilities.

3. Based on leading-edge technology applications, lip seal vs mechanical seal has achieved great success with its highest quality. To function as a front-runner of mechanical seals houston business is the objective of Dms Seals Technology Co.,limited. Inquire online!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US