DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer Custom rotary seals manufacturer factory for aviation

1. DMS Seal Manufacturer rotary seals manufacturer has been designed with advanced systems. These systems include machine control systems, PLC system, variable speed drive and servo system.

2. DMS Seal Manufacturer has been verified to meet various quality requirements. It has been tested to work properly under various conditions, even harsh conditions.

3. The production process of DMS Seal Manufacturer includes several major production processes, namely, material opening and cleaning, fiber loosening, grinding, dyeing and printing.

4. The product has reliable and consistent quality thanks to the detailed quality inspection throughout the whole production.

5. The product is quality-assured as it has been stringently tested on various parameters before coming into the market.

6. The product has been tested for many times under the rigorous quality control system.

7. The product has passed ISO 90001 quality certification.

8. Our professional testing people will help customers conduct testing for the quality of rotary seals manufacturer .

9. The assurance of will contribute to the development of DMS Seal Manufacturer.

10. Active listening is essential for Dms Seals Technology Co.,limited's effective communication with customers.

11. Dms Seals Technology Co.,limited sets deep root in rotary seals manufacturer market successfully mainly for its high quality.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

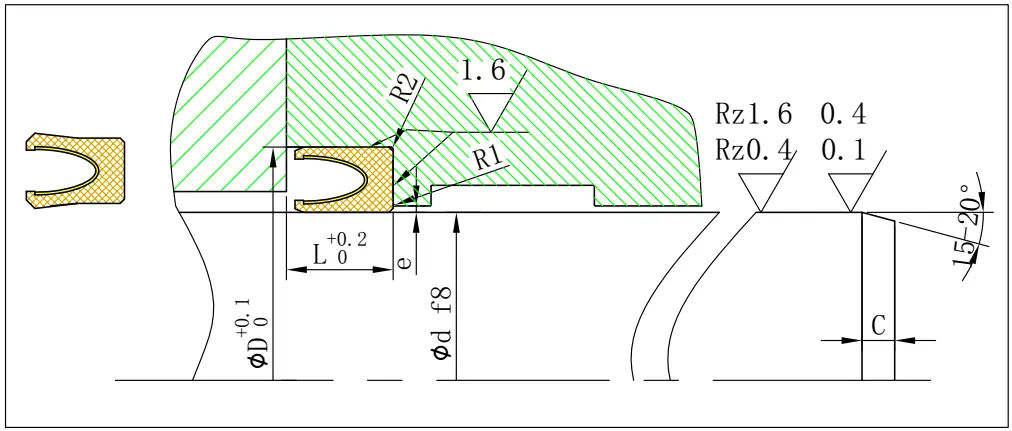

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Equipped with the most advanced machines, Dms Seals Technology Co.,limited is a professional manufacturer for rotary seals manufacturer . DMS Seal Manufacturer is one of primary brands that is committed to shaft seals for dynamic applications industry. With years of factory experience in mechanical shaft seals springs , Dms Seals Technology Co.,limited has grown to be a leader for exporting in China. With high reputation, DMS Seal Manufacturer has set foot in more places in the world.

2. Dms Seals Technology Co.,limited has advanced production equipments and rich technical strength. Dms Seals Technology Co.,limited has a sound management system and abundant production experience. The professional excellent talents unite a powerful and creative team of design in Dms Seals Technology Co.,limited. Based on the application of leading technology, spring energized seal design has made great achievement in its finest quality. Dms Seals Technology Co.,limited has a number of high-level knowledge and technical staff to help better guarantee the quality of mechanical seal problems .

3. Sustainable practices are embedded into our value chain. We are committed to managing our economic, environmental and social impacts throughout our value chain. At the core of our company are our employees and values. We encourage our valued, talented team to be driven to our company goals based around Quality, Delivery, and Service. We constantly work together with our clients. We implement measures to mitigate and adapt to the effects of climate change, as well as identify and manage the risks of natural disasters.

DMS Seal Manufacturer Custom rotary seals manufacturer factory for aviation

rotary seals manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US