DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer Custom piston seals manufacturers for light and medium hydraulic systems

1. DMS Seal Manufacturer has a scientific design. It is made according to environmental/climatic factors such as light, temperature, wind, sound, touch or with occupant/user needs. DMS Seals implements and optimizes its quality control systems

2. This product supports every movement and every turn of the body’s pressure. And once the weight of the body is removed, the mattress will return to its original shape. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

3. The product is safe to wear. Its fabrics have gone through the ingredient test to make sure no harmful substances are contained. To reduce costs with high-efficiency work is the DMS's purpose

4. This product is able to resist impacts without any deformation. It has no tendency to crack or break under repeated stress from the foot. We can support OEM and ODM

5. This product features visual balance. Surface designs on this product including color, line, and texture are utilized to construct this balance . DMS Seals takes the lead in grasping the development trend of the industry

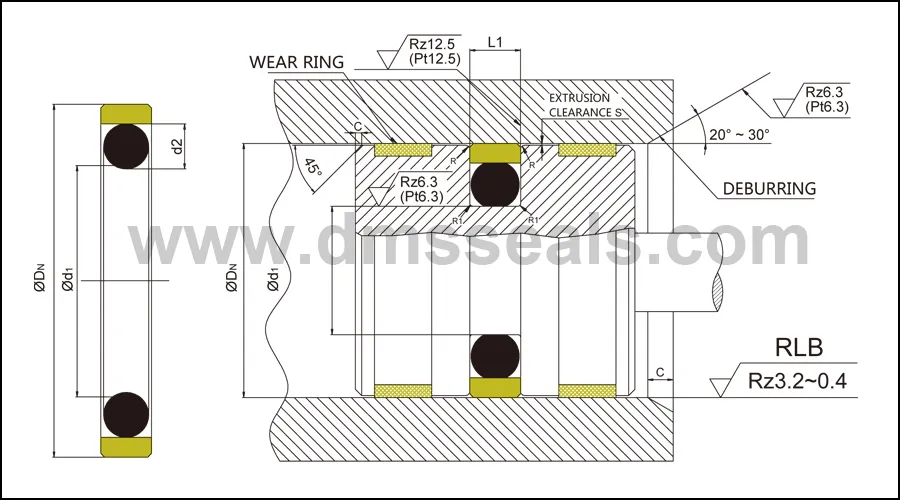

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. After years of dedication in manufacturing , Dms Seals Technology Co.,limited now becomes a pioneer in this industry and enters the international markets.

2. Our professional equipment allows us to fabricate such .

3. To stand tightly in the market of piston seals , Dms Seals Technology Co.,limited will put quality in the first place. Inquiry!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US