DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer combined o-ring seal with nbr or fkm o ring for light and medium hydraulic systems

1. DMS Seal Manufacturer hydraulic piston seals has a good design. Its elements are programmed to respond to climatic factors, to improve energy efficiency or reduce solar heat, or for aesthetic reasons such as an art installation. The high pressure seals have strong wear resistance to hard conditions

2. Coming with expectations of reduced utility bills and fewer repair bills, this product would be an attractive feature in any place. We have developed solutions of the sealing of special working condition

3. o-ring seal are recognized for their characteristics of hydraulic piston seals . DMS o-ring seal has advanced machines and equipment for its production

4. o-ring seal is good at all working conditions with hydraulic piston seals and longer life span. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

Application and properties

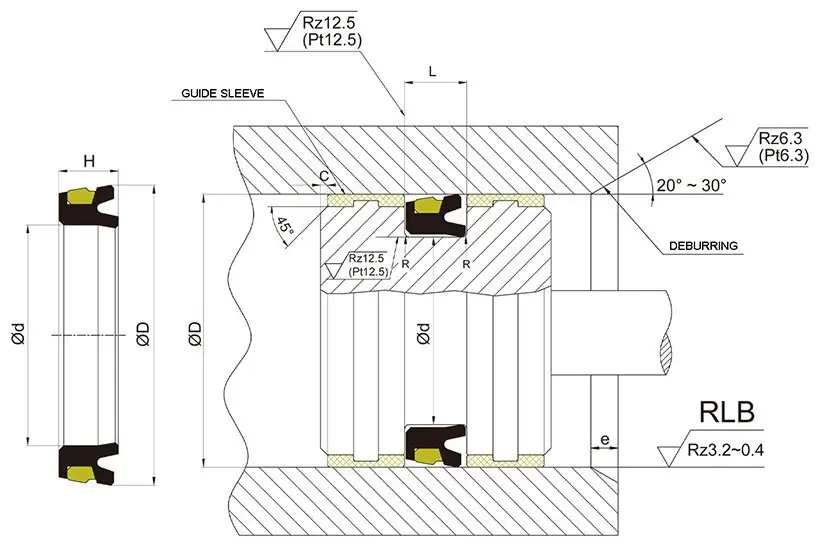

Apply to the hydraulic cylinder of piston sealing, generally used in conjunction with the guide sleeve. The seal ring and piston conforming to be a symmetric section to achieve the sealing performance. The Non-standard Y-ring has the function of sealing and provides the elastic force to the sealing ring and compensates for the abrasion. Very high pressure stability under pressure and harsh conditions, high wear resistance, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

Y-Ring: NBR / PU

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L+0.2 | e | Order No. |

40 | 32 | 7 | 7.5 | 6 | DDA40*32*7.5 |

45 | 37 | 7 | 7.5 | 6 | DDA45*37*7.5 |

55 | 45 | 7 | 7.5 | 6 | DDA55*45*7.5 |

63 | 48 | 12 | 13 | 6 | DDA63*48*13 |

70 | 55 | 12 | 13 | 6 | DDA70*55*13 |

80 | 65 | 12 | 13 | 6 | DDA80*65*13 |

90 | 75 | 12 | 13 | 7 | DDA90*75*13 |

105 | 90 | 12 | 13 | 7 | DDA105*90*13 |

120 | 105 | 12 | 13 | 7 | DDA120*105*13 |

140 | 120 | 12 | 13 | 7 | DDA140*120*13 |

160 | 140 | 12 | 13 | 10 | DDA160*140*13 |

180 | 160 | 16 | 17 | 10 | DDA180*160*17 |

200 | 180 | 16 | 17 | 10 | DDA200*180*17 |

Company Features

1. Dms Seals Technology Co.,limited has strong economic strength and technical strength.

2. We emphasize customer focus. We ensure that all aspects of the company put customer satisfaction first. Welcome to visit our factory!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US