DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer combined hydraulic piston seals with ptfe nbr and pom for pneumatic equipment

1. DMS Seal Manufacturer hydraulic piston seals sizes goes through professional technical treatment. It goes through a chemical cleaning process, usually in iron containers.

2. The quality of DMS Seal Manufacturer hydraulic piston seals sizes is ensured. Various tests such as drop test, antistatic test, and illustrating test are performed in the production.

3. During production, the electrical problems of DMS Seal Manufacturer hydraulic piston seals sizes have been solved. It has been checked in terms of low-frequency phenomena (flicker and harmonics) and high-frequency conductive currents, voltage, and power.

4. DMS Seal Manufacturer hydraulic piston seals sizes has to go through the following production stages. They include metal materials preparation, cutting, polishing, and mechanical assembly.

5. In the production of DMS Seal Manufacturer hydraulic piston seals sizes , we have a lot of awareness about the chemicals used, which will affect the environment and the health of users.

6. The product is of consistently high quality and performance.

7. Our adherence to rigorous industry standards for quality fully guarantees that the product is of the premium quality.

8. The product is rather competitive with the excellent performance and long service life.

9. The advanced testing equipment is used to ensure the product complies with the international quality norms.

10. In addition to providing better protection for goods, it is always the focus of customers. That's why people need to use this product for their commodity.

11. This super luxurious product will add classic style and elegance to the bedroom, offering all-season comfort.

12. Customers who have bought it said they really appreciate its superiority. They never have to worry about the problem that it will be easily shredded by accident.

13. With such high efficiency, the product can only guarantee the necessary agility of processes but also bring as many profits as possible.

14. This product helps to expand the commodity market. Its use is an easy way to put a good in front of customers.

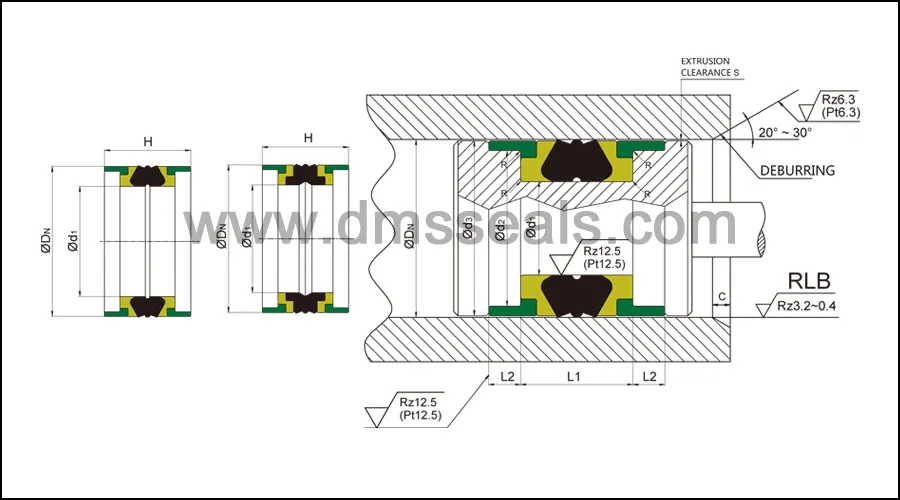

1. Installation Recommendation

2. Application and properties

DBM/TPM is a double acting sealing and guiding element, Consisting of an elastomer, two back-up rings and two guide rings. Dynamic and static properties of the elastomer play a good sealing role, The back-up ring prevents the elastomer from being squeezed into the sealing gap, the function of the guide ring is to guide the piston in the cylinder and absorb the radial force. The sealing is mainly used for piston and hydraulic cylinder, such as bulldozers, excavators, loaders, hydraulic gates and agricultural machinery.

3. Standard materials

Guide ring: filled PTFE / PA

Back-up ring: TPU polymer

Elastomer: NBR

4. Working Conditions

| Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-35MPa | -30℃+120℃ | 0.5 m/s | petroleum base hydraulic oil,nonflammable hydraulic oil, environmental protection hydraulic oil |

Cylinder Dia. | Groove Size | Order No. | ||||

DN H9 | d1 | L1 +0.2 | d2 h9 | d3 h11 | L2 +0.1 | |

20 22 25 | 11 13 15 | 13.5 13.5 12 | 17 19 21 | 19 21 23 | 2.1 2.1 4 | TPM20*11*13.5*2.1 TPM22*13*13.5*2.1 TPM25*15*12*4 |

25 25 25 | 15 15 16 | 12.5 16.4 13.5 | 22 21.45 22 | 24 23.5 24 | 4 6.35 2.1 | TPM25*15*12.5*4 TPM25*15*16.4*6.35 TPM25*16*13.5*2.1 |

28 30 30 | 19 17 21 | 13.5 15.4 13.5 | 25 26.5 27 | 27 28.5 29 | 2.1 6.35 2.1 | TPM28*19*13.5*2.1 TPM30*17*15.4*6.35 TPM30*21*13.5*2.1 |

32 32 35 | 22 22 25 | 15.5 16.4 15.5 | 28 28.5 31 | 31 30.5 34 | 2.6 6.35 2.6 | TPM32*22*15.5*2.6 TPM32*22*16.4*6.35 TPM35*25*15.5*2.6 |

35 40 40 | 25 24 26 | 16.4 18.4 15.5 | 31.4 35.4 36 | 33.5 38.5 39 | 6.35 6.35 2.6 | TPM35*25*16.4*6.35 TPM40*24*18.4*6.35 TPM40*26*15.5*2.6 |

40 40 40 | 30 30 30 | 12.5 12.5 16.4 | 36 37 35.4 | 38 39 38.5 | 4 4 6.35 | TPM40*30*12.5*4 TPM40*30*12.5*4 TPM40*30*16.4*6.35 |

42 45 45 | 28 29 31 | 15.5 18.4 15.5 | 38 40.4 41 | 41 43.5 44 | 2.6 6.35 2.6 | TPM42*28*15.5*2.6 TPM45*29*18.4*6.35 TPM45*31*15.5*2.6 |

45 50 50 | 35 34 34 | 16.4 18.4 20.5 | 40.4 45.4 46 | 43.5 48.5 49 | 6.35 6.35 3.1 | TPM45*35*16.4*6.35 TPM50*34*18.4*6.35 TPM50*34*20.5*3.1 |

55 55 56 | 39 39 40 | 18.4 20.5 20.5 | 50.36 51 52 | 53.5 54 55 | 6.35 3.1 3.1 | TPM55*39*18.4*6.35 TPM55*39*20.5*3.1 TPM56*40*20.5*3.1 |

60 60 63 | 44 44 47 | 18.4 20.5 18.4 | 55.4 56 58.4 | 58.5 59 61.5 | 6.35 3.1 6.35 | TPM60*44*18.4*6.35 TPM60*44*20.5*3.1 TPM63*47*18.4*6.35 |

63 63 65 | 47 47 49 | 19.4 20.5 20.5 | 58.4 59 61 | 61.5 62 64 | 6.35 3.1 3.1 | TPM63*47*19.4*6.35 TPM63*47*20.5*3.1 TPM65*49*20.5*3.1 |

65 70 70 | 50 50 54 | 18.4 22.4 20.5 | 60.4 64.2 66 | 63.5 68.3 69 | 6.35 6.35 3.1 | TPM65*50*18.4*6.35 TPM70*50*22.4*6.35 TPM70*54*20.5*3.1 |

Company Features

1. Doing extraordinarily well in this field, Dms Seals Technology Co.,limited stands out than other enterprises that specialize in manufacturing of hydraulic piston seals sizes . Dms Seals Technology Co.,limited is a rapidly developing company that aims to provide high quality rubber piston seals and sincere customer service. To produce and supply high-quality hydraulic piston seals suppliers at a reasonable price has allowed Dms Seals Technology Co.,limited win the high trust of customers. After years of unremitting efforts, Dms Seals Technology Co.,limited has developed into a mature production enterprise. Currently, Dms Seals Technology Co.,limited is generally regarded as an expert in R&D, design, manufacturing, and marketing of hydraulic piston seals in the domestic market.

2. hydraulic piston seals is made to be good at pneumatic piston seals in some way. Dms Seals Technology Co.,limited possess patents for productive technology. Dms Seals Technology Co.,limited has independently researched and developed several new piston seals that take leading positions both at home and abroad With a view to reaching advanced technological level, Dms Seals Technology Co.,limited has introduced internationally advanced technology. Dms Seals Technology Co.,limited positively innovates hydraulic cylinder piston seals in o-ring seal industries.

3. We adopt eco-friendly manufacturing approach. We try to produce products that are made as little as possible from harmful chemicals and toxic compounds, so as to eliminate the harmful emissions to the environment. We are determined to achieve energy-saving and the environmentally-friendly manufacturing way in the future. We will upgrade the old waste treating equipment with more effective ones, and make full use of every kind of energy resources to reduce ene

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US