DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer bronze filled hydraulic rod seals glyd ring for larger piston clearance

1. DMS Seal Manufacturer hydraulic oil seal is fabricated using quality raw materials and advanced production technology. The high pressure seals have strong wear resistance to hard conditions

2. The product has gained a good reputation in the industry, promoting its wider market application. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

3. Our quality experts test this product on different parameters, so as to maintain the quality. DMS Seals provides professional design and production of high-grade o-ring seals

4. The product can be used for a relatively long time thanks to its high quality materials. DMS Seal manufacturer was established in 2008 and now has more than 10 years professional experience

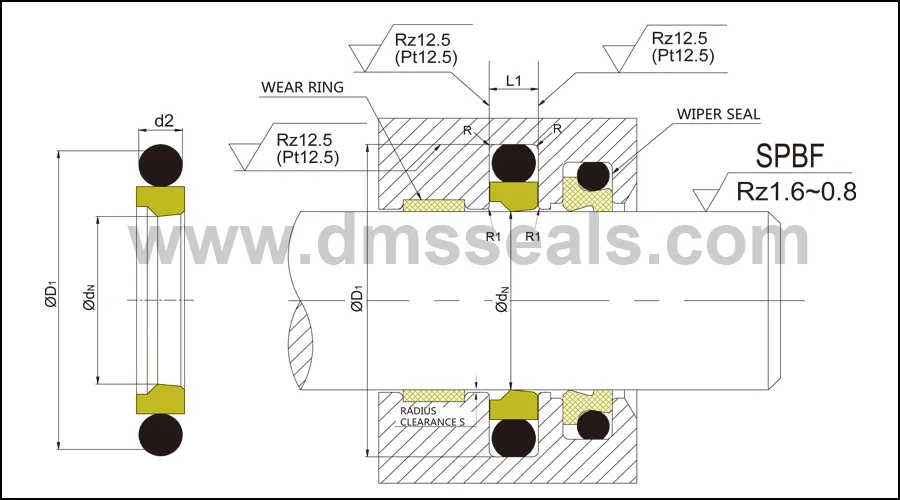

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation.

Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

4 5 6 | 8.9 9.9 10.9 | 2.2 2.2 2.2 | GSJ4*8.9*2.2 GSJ5*9.9*2.2 GSJ6*10.9*2.2 | 5.28*1.78 6.75*1.78 7.65*1.78 |

8 8 10 | 12.9 15.3 14.9 | 2.2 3.2 2.2 | GSJ8*12.9*2.2 GSJ8*15.3*3.2 GSJ10*14.9*2.2 | 9.25*1.78 10.77*2.62 11.8*1.78 |

10 12 12 | 17.3 16.9 19.3 | 3.2 2.2 3.2 | GSJ10*17.3*3.2 GSJ12*16.9*2.2 GSJ12*19.3*3.2 | 12.37*2.62 13.3*1.78 13.94*2.62 |

14 14 15 | 18.9 21.3 19.9 | 2.2 3.2 2.2 | GSJ14*18.9*2.2 GSJ14*21.3*3.2 GSJ15*19.9*2.2 | 15.6*1.78 15.54*2.62 16.67*1.78 |

15 16 16 | 22.3 20.9 23.3 | 3.2 2.2 3.2 | GSJ15*22.3*3.2 GSJ16*20.9*2.2 GSJ16*23.3*3.2 | 17.12*2.62 17.17*1.78 18.72*2.62 |

18 18 19 | 22.9 25.3 29.7 | 2.2 3.2 4.2 | GSJ18*22.9*2.2 GSJ18*25.3*3.2 GSJ19*29.7*4.2 | 18.77*1.78 20.29*2.62 23.39*3.53 |

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

Company Features

1. Being excellent in improving the quality of hydraulic rod seals , Dms Seals Technology Co.,limited has won customer's trust. we have successfully developed a variety of glyd ring series.

2. Our advanced machine is able to fabricate such rod seal with features of [拓展关键词/特点].

3. Our quality is our company name card in piston seals industry, so we will do it best. Customers’ satisfaction is a core value for the growth and profitability of our company. This satisfaction first relies on the quality of our teams. We would like to make efforts to convince customers that we have the responsibility, ability, and expertise to offer what they really need. Contact us!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US