DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer Best spring energized seals for aviation

- Dms Seals adopts the strategy of the two-way interaction between enterprise and consumer. We gather timely feedback from dynamic information in the market, which enables us to provide quality services.

1. Touch-Based Technology: the screen of DMS Seal Manufacturer spring energized seals adopts touch-based technology, which is also known as an electromagnetic touch screen. It is developed by our dedicated R&D staffs.

2. For DMS Seal Manufacturer to be produced, raw materials, water, and additives are required. All primarily related building materials are delivered to the factory and stored properly.

3. During production, DMS Seal Manufacturer is strictly inspected. Defects have been carefully checked for poor lasting, incomplete bonding, and stitching errors.

4. The design of DMS Seal Manufacturer spring energized seals is completed by using the template provided by our customers. It is strictly carried out by complying with the dimensions and printing requirements.

5. The manufacturing process of DMS Seal Manufacturer is sustainable. This includes prioritizing the responsible sourcing of ingredients, implementing earth-friendly manufacturing method, and experimenting with inventive recycling programs.

6. The luster of the product is determined by the reflectivity, refractive index, or absorptivity of the product. The better the luster, the higher the visible light reflectivity.

7. The product is corrosion resistance. The stainless steel parts have been electroplated with a layer of metal membrane to resist the chemical influence.

8. This product is eco-friendly and harmless. The materials or parts used in it are guaranteed to meet the environmental protection standards of European and American.

9. Dms Seals Technology Co.,limited has the right for direct import and export.

10. Remarkable success has been achieved by Dms Seals Technology Co.,limited in spring energized seals field.

11. Our company provides different types of spring energized seals for your selection.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

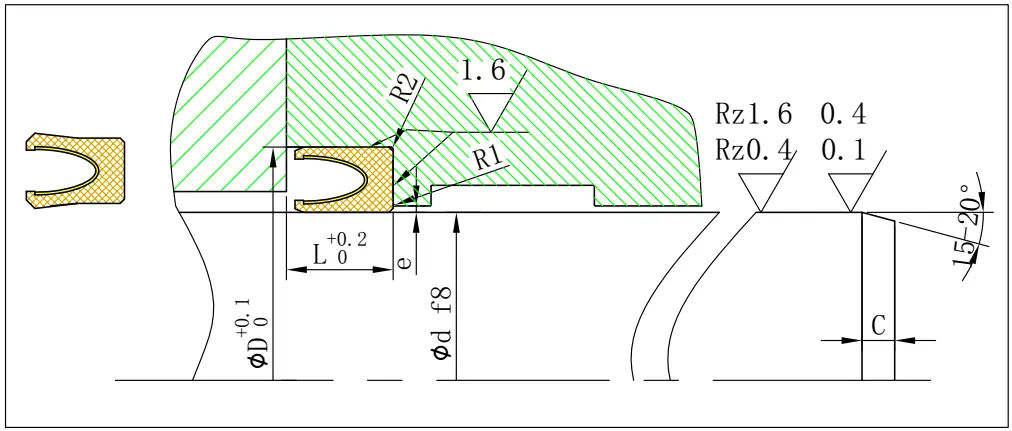

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is a developing technology entrepreneur in the industry. Dms Seals Technology Co.,limited, as one the biggest developer & manufacturer of in China, has grown into a professional provider in this industry. Dms Seals Technology Co.,limited has been specializing in R&D, design, manufacture, and sales, offering high quality for many years.

2. Dms Seals Technology Co.,limited has strong technical force, strict quality management system and perfect after-service mechanism. The improvement of technical force also facilitates the development of DMS Seal Manufacturer. Dms Seals Technology Co.,limited has a number of scientific and technological talents engaged in the development, research and production of spring energized seals products for many years. Promoting the harmonious development of scientific and technological ensures the competitiveness of DMS Seal Manufacturer in spring loaded seal industry.

3. DMS Seal Manufacturer sincerely wishes you a success in your business transaction. Contact! Dms Seals Technology Co.,limited believes it will grow into the first brand of world's oil seal spring. Contact! Every employee is making Dms Seals Technology Co.,limited a strong competitor on the industry. Contact!

DMS Seal Manufacturer Best spring energized seals for aviation

spring energized seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US