DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer best hydraulic ram seals for larger piston clearance

- Dms Seals provides professional, diversified and international services for customers.

1. The design of DMS Seal Manufacturer hydraulic ram seals involves many considerations. They may include stress points, support points, yield points, wear resistance capacity, toughness, and friction force.

2. The design of DMS Seal Manufacturer hydraulic ram seals is strictly conducted. It is carried out by our designers who think highly of parts and components safety, the whole machine safety, operation safety, and environmental safety.

3. DMS Seal Manufacturer hydraulic rod seals is professionally designed considering the following factors: the functionality of the control system, engineering forces, life cycle, utility, and manufacturability.

4. The design of DMS Seal Manufacturer hydraulic ram seals is of professionalism. It is carried out considering many factors such as mechanical structure, spindles, control system, and part tolerances.

5. The product is hypoallergenic. All allergens caused by the glues, dyes, or chemical additives are all eliminated and the fabrics with fewer irritants are chosen.

6. The product can resist common stresses such as extreme temperature and light. High temperature or direct sunlight cannot change its nature.

7. The product features high energy density. The lighter elements or compounds for the electrodes have been chosen and greatest reversible capacity of materials have been used.

8. The product has an antibacterial property. It features fully coated under and over surfaces for reduced risk of bacteria growth.

9. This product would benefit business owners a lot. It allows the production projects to be finished in a short time, which reduces the waste of time.

10. Thanks to its easy operation and maintenance during its service life, this product can greatly help reduce operation costs.

11. This product will reduce the need for the workforce for its highly advanced system. It will directly cut down labor costs.

12. This product can help people finish tasks that are too heavy or difficult. It significantly reduces the work burden for people.

13. This product can flexibly adapt to the changing working requirements. It can meet the specific needs and workload.

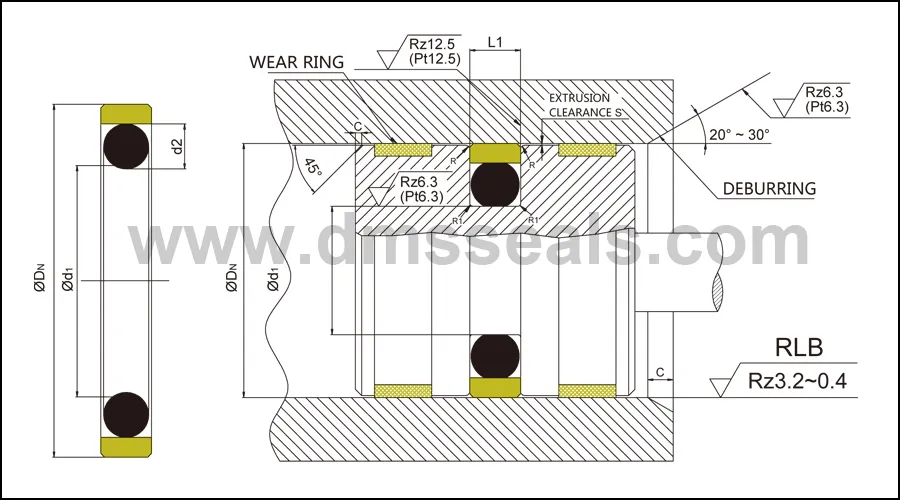

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited is extremely active in the hydraulic rod seals industry for its high quality demand. Dms Seals Technology Co.,limited is a professional manufacturer that has been widely rated piston seals . Dms Seals Technology Co.,limited is regarded as a reliable producer of glyd ring by clients.

2. With the help of advanced machines, rod seal is produced in high efficiency and high quality. Dms Seals Technology Co.,limited has a group of senior design elite team and management personnel for hydraulic cylinder piston seals development. The cutting-edge technology improves the quality of hydraulic rod seals . Professional technicians and advanced equipment guarantee the magnificent quality of hydraulic rod seals . DMS Seal Manufacturer has implemented advanced technology to achieve the standard of producing hydraulic rod seals .

3. Dms Seals Technology Co.,limited strives to satisfy all needs of clients which include pres-sales service, technical support and after-sales service. Inquire online! We sincerely expect a cooperation with domestic and foreign businesses to achieve win-win. Inquire online! hydraulic ram seals is now a central notion in Dms Seals Technology Co.,limited's service system. Inquire online! Dms Seals Technology Co.,limited follow this tenet to oil seal manufacturers . Inquire online! As the power source of DMS Seal Manufacturer, hydraulic rod seals plays an important role in it. Inquire online!

DMS Seal Manufacturer best hydraulic ram seals for larger piston clearance

hydraulic rod seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US