DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer bearing element wear ring for sale

- Dms Seals puts customers first and strives to provide them with quality and considerate services.

1. The design of DMS Seal Manufacturer rubber seal design uses the principle of humanization, which means it considers the mindset and habits of how shoppers walk while buying items.

2. DMS Seal Manufacturer rubber seal design is developed by the R&D team who have spent years investigating water improvement. The team creates this product with the purpose of reducing or removing all contaminants that are present in the water.

3. The design of DMS Seal Manufacturer rubber seal design is to meet the characteristics of goods being displayed and the brand’s culture. It is always made after the designers grasp the features of the goods, brand strength and brand culture.

4. DMS Seal Manufacturer rubber seal design is finished after going through a series of production procedures, including materials mixing, hot melting treatment, vacuum cooling, quality inspection, etc.

5. The metal ingredients of DMS Seal Manufacturer bearing element are under strict control. Lead, mercury, and cadmium in the battery cells are tested to rigorously to meet the mandatory standards put forward by the State Environmental Protection Administration.

6. It will go through multiple processes to make quality guaranteed before loading.

7. The quality of this product is more assured by stressing the value of quality management.

8. The function of the product has been continually improved by our dedicated R&D team.

9. The product is of high quality and works exceptionally well.

10. The product has stand in a reputable position in the market.

11. The product presents an opportunity for building customer trust and winning more business.

12. The product has a wide range of applications in the industry.

13. The product is consistency with the latest trends in the market and widely accepted by customers.

14. The huge user base gives a huge impetus to this product.

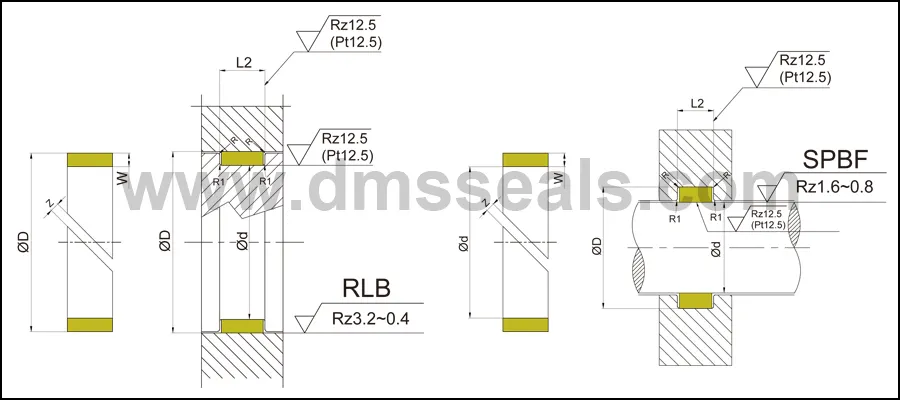

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Filled PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited has built the global network for R&D, production, and sales of rubber seal design not only in China but also across the world. Dms Seals Technology Co.,limited is stronger than ever in the R&D and manufacturing of bearing element . We have been staying competitive in the markets for years. Dms Seals Technology Co.,limited is equipped with modern production lines to manufacture oil seal manufacturer. Surpassing many other suppliers who produce rubber seal ring manufacturers, Dms Seals Technology Co.,limited is thought highly of in terms of its premium quality and sincere services.

2. We have an experienced marketing team who forms their own complete marketing system. They are quite familiar with market trends and clients' purchasing tendency. This enables them to master clients' actual demands. We have a team of dynamic customer service members. They are well-equipped with different languages and strong communication abilities. This enables them to better understand and solve customers' concerns and problems. We are backed by our professional R&D team. Equipped with years of expertise in the industry, they are able to quickly develop new products according to the newest market trend. Over the years, we have been honored with different titles. They are 'China Credible Enterprise', 'Complaint-free Enterprise', and 'High-Integrity Enterprise'. These honors demonstrate our overall comprehensive strength.

3. We aim to become the employer of choice by providing an open platform for staff communication, development, and recognition to enhance the self-initiatives in pursuing excellence for staff to take pride in. We will increase our positive social impact through a range of sustainable strategies. We source sustainable raw materials, implement strict control on water usage, wastes discharge, and greenhouse gas emissions. We launch various sustainable plans to achieve a balance between economic growth and environment friendlessness. For instance, we recycle or handled unpreventable and harmful wastes complying with relevant standards prior to release or transfer. We commit to an improved environment. We take all efforts to transform into a lean manufacturing way that aims to reduce wastes and pollution, so as to reduce our carbon footprint. Customers can be sure that their products — whatever stage of the process — are under our strict production control and in the hands of experts at all times. Inquire now!

DMS Seal Manufacturer bearing element wear ring for sale

bearing element

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US