DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer bearing contact guide strip for sale

1. DMS Seal Manufacturer is dyed with an accurate combination of pressure, temperature and time. Through this process, its color effect is satisfactory.

2. DMS Seal Manufacturer follows the principles of five fashion design principles, rhythm, unity, balance and proportion, as well as outstanding and conspicuous design.

3. DMS Seal Manufacturer is evaluated by the processing technology to ensure that the sewing, construction and decoration meet international clothing standards.

4. 品牌名称] meets safety standards. Testing of raw silk, finished textiles, dyes, and accessories ensure the safety of the finished product.

5. The product features ease of use. The display gives full visualization of current machine status, including cycle time, idle time, efficiency, and parts life status.

6. This product is available in a wide selection of colors, including all of the standard colors that conventional bedding comes.

7. The product is distinctive for user-friendliness. It is designed with desired operation functions according to its applied characteristics.

8. Dms Seals Technology Co.,limited closely follows bearing contact overall development and comprehensively promotes management reforms.

9. Dms Seals Technology Co.,limited can give full inspection for the whole manufacturing process to ensure quality.

10. Dms Seals Technology Co.,limited has selected a large number of professional technical talents and design talents.

11. helps Dms Seals Technology Co.,limited to stand out in bearing contact market.

12. Our main business focuses on the development and production of high quality bearing contact , which creates our leadership in the field of .

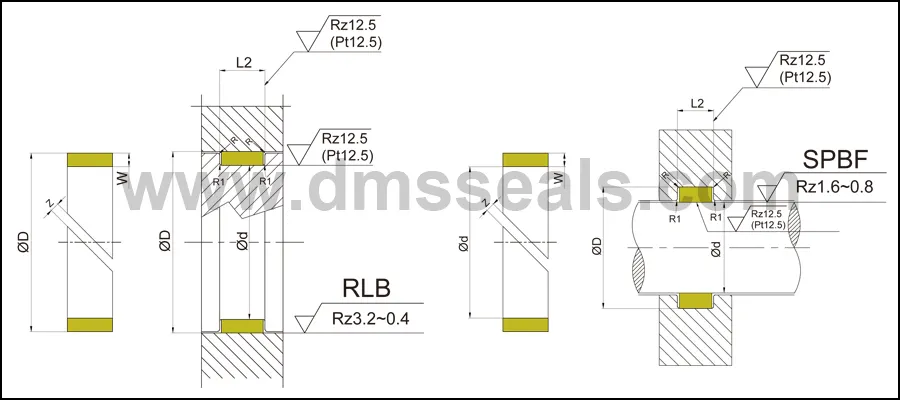

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Phenolic resin

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | 0-100 MPa | -60℃ +120℃ | 1 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Standard groove width and standard thickness

Standard groove width

Groove width L2 | 8.1 | 10 | 15 | 20 | 5.6 | 6.3 | 9.5 | 9.7 | 12.7 | 25 | 30 | 40 | 50 | 5 | 6 | 8 | 35 | 45 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 2 | 2.5 | 3 | 3.5 | 4 | 6 | 3.18 | 3.17 |

The products of various thickness could be provided.

Company Features

1. In a good market environment, Dms Seals Technology Co.,limited has grown quickly in the field of bearing contact . Dms Seals Technology Co.,limited is a top manufacturer who's particularly good at producing DMS Seal Manufacturer. After years of steady development, Dms Seals Technology Co.,limited has grown to be a leading manufacturer of needle rollers manufacturers . With premium excellent service, Dms Seals Technology Co.,limited has a high reliability in the market. Dms Seals Technology Co.,limited has long been committed to the creation, production and sales of single ball bearing roller .

2. Dms Seals Technology Co.,limited has advanced machines to produce high-quality roller bearing number . DMS Seal Manufacturer has got its popularity for its high quality radial needle bearing . Dms Seals Technology Co.,limited has great advantages in talent and research.

3. DMS Seal Manufacturer is confident to provide you the most comprehensive services and products of high quality. Get quote! Dms Seals Technology Co.,limited is committed to conducting its business in a socially responsible manner. Get quote! Dms Seals Technology Co.,limited is a company who sticks to customer first always. Get quote!

DMS Seal Manufacturer bearing contact guide strip for sale

bearing contact

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US