DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Custom seals for hydraulic pumps with nbr or fkm o ring for sale

1. DMS Seal Manufacturer is meticulously designed. Its development takes into considerations that operational efficiency, functionality, productivity, component performance, operation safety, etc.

2. DMS Seal Manufacturer seals for hydraulic pumps must be tested to be in compliance with general standards. It has been tested for machinery directive, operation safety, and life expectancy.

3. DMS Seal Manufacturer has a revolutionary design. It is a result of the expertise of professionals such as architects, manufacturers, and installers.

4. This product is safe to use. With its built-in protective systems, including overload and overvoltage protective devices, it generates no danger.

5. The product is built to last. Its mechanical components can resist the aging effect and overload that caused by long-time working.

6. The product works stable even in a humid environment. It does not prone to break down even the relative humidity of air is high.

7. The product is characterized by energy efficiency. With its strong energy conversion capacity, it consumes only little energy to run as efficiently as possible.

8. The tight weaving of the microfibers does cause any liquid to form beads on the surface of the fabric and stay for a short time, rather than soaking immediately.

9. Generally, the use of this product is the simplest and effective way to advertise the brand. This is because the use of it aids in branding the merchandise to the retailers and consumers.

10. This product can give the wearer a variety of feelings, such as fashion, beauty and radiation protection.

11. The product is characterized by practicality, comfort and art. It is very popular among modern people has has been exported to many countries.

12. It can be designed with woven patterns which are often intricately detailed, allowing it to add a touch of color and decor to the room.

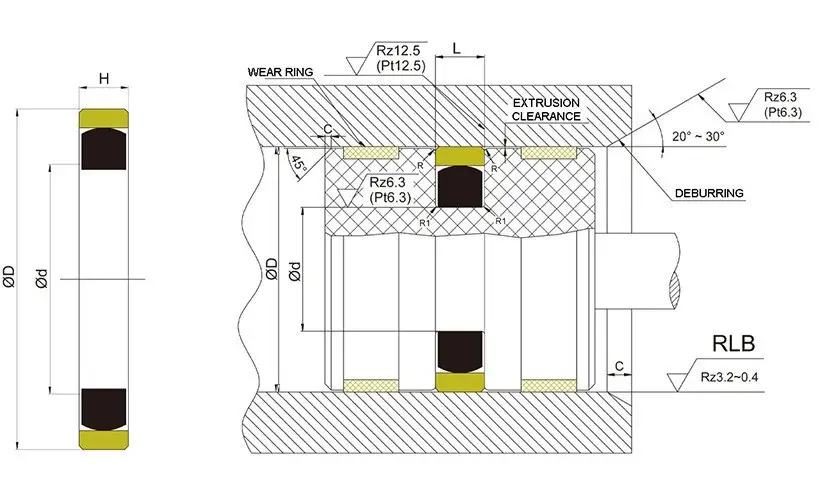

Bore Diameter | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | |||

D H8 | d h8 | L1+0.2 | R1 | 16MPa | 26MPa | 32MPa | 40MPa |

55.0-149.9 | D-10.0 | 10.0 | 0.4 | 0.60 | 0.50 | 0.40 | 0.40 |

150.0-244.9 | D-12.5 | 12.5 | 0.4 | 0.75 | 0.65 | 0.55 | 0.50 |

245.0-500.0 | D-15.0 | 15.0 | 0.8 | 0.75 | 0.65 | 0.55 | 0.50 |

500.1-760.0 | D-17.5 | 17.5 | 1.2 | 0.75 | 0.65 | 0.55 | 0.50 |

760.1-999.9 | D-20.0 | 20.0 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

≧1000 | D-20.0 | 20.5 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

Application and properties

Applied to the hydraulic cylinder of heavy machinery and metallurgical equipment. Pressure resistance and corrosion resistance are strong, good thermal conductivity,structure anti-distortion, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+100℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. |

D H8 | d h8 | L+0.2 | |

55 | 40 | 10 | GSF-W55*40*10 |

80 | 60 | 10 | GSF-W80*60*10 |

110 | 90 | 10 | GSF-W110*90*10 |

130 | 110 | 10 | GSF-W130*110*10 |

160 | 135 | 12.5 | GSF-W160*135*12.5 |

180 | 155 | 12.5 | GSF-W180*155*12.5 |

200 | 175 | 12.5 | GSF-W200*175*12.5 |

215 | 190 | 12.5 | GSF-W215*190*12.5 |

230 | 205 | 12.5 | GSF-W230*205*12.5 |

Company Features

1. As a company with years of experience in domestic and foreign market sales, Dms Seals Technology Co.,limited is a highly reputable company specializing in the manufacturing of . No one compares Dms Seals Technology Co.,limited in creating . Since our inception, we have been a consistent and trusted partner, providing a quality product to customers. Dms Seals Technology Co.,limited is an international, China-based manufacturing company with a strong production foundation and marketing experience.

2. We are proud to have an excellent technical team to produce seals for hydraulic pumps with outstanding performance. The application of high technology is conducive to the production of cheap oil seals . Due to the efforts of skilled technicians, rubber piston rings have become more competitive in this industry. Dms Seals Technology Co.,limited owns a patented technology in its shaft seal design . DMS Seal Manufacturer has been committed to the development and manufacture of new technologies hydraulic piston seals suppliers .

3. In order to win the market, DMS Seal Manufacturer has been doing the utmost to serve customers with the most professional attitude. Please contact. Dms Seals Technology Co.,limited adheres to the concept of customer first. Please contact. Every worker is making Dms Seals Technology Co.,limited a powerful competitor on the market. Please contact. Dms Seals Technology Co.,limited will help you better increase your benefits. Please contact. Our goal is to make every customer enjoy highly rated DMS Seal Manufacturer service. Please contact.

Custom seals for hydraulic pumps with nbr or fkm o ring for sale

seals for hydraulic pumps

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US