DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Custom rod end seals for reciprocating piston rod or piston single acting seal

- Dms Seals has a comprehensive service system covering from pre-sales to after-sales. We are able to provide one-stop and thoughtful services for consumers.

1. The design of DMS Seal Manufacturer rod end seals is diverse in style.

2. With vibrant designs and colors, may just be the best rod end seals .

3. The design of rod end seals meets modern tendency.

4. Considering high demand material requirements for material, rod end seals is made up of .

5. The product features the desired safety. The metal materials used for electric conductors and insulating materials used for the prevention of accidental contact have been strictly controlled.

6. The product has stable performance under extreme weathers. It does not prone to affect by thundering and lightning, storms, or humid weather.

7. The product is environmental-friendly. Any heavy metals such as lead, mercury, cadmium have been eliminated, and the ingredients of them do not exceed 0.0001%.

8. The product stands out for its overload protection system. It is built with effective fuses and circuit breakers to prevent electrical hazards caused by overloading.

9. Dms Seals Technology Co.,limited cooperates with many well-known domestic and foreign brands for OEM cooperation.

10. rod end seals is deeply trusted by customers for its excellent quality.

11. The quality of rod end seals is tested again and again before delivery.

12. It is beneficial for DMS Seal Manufacturer to pay attention to the importance of rod end seals quality.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

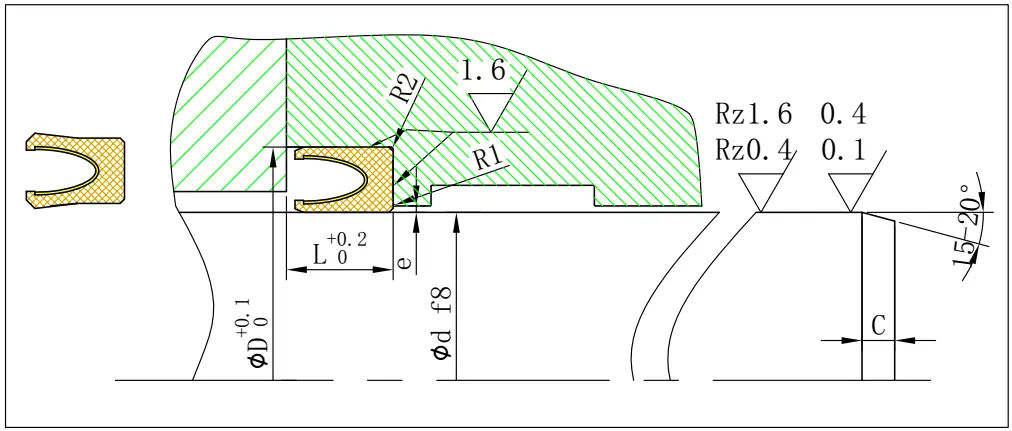

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is a vanguard enterprise in the rod end seals industry in China. Due to our endless creative energy and reliable quality, DMS Seal Manufacturer is selected by several international rotating mechanical seal brand names as their OEM manufacturing partner. Lots of people choose DMS Seal Manufacturer for garter spring seal , which owns to Dms Seals Technology Co.,limited's leading status in global market. Not content with great success in domestic market, Dms Seals Technology Co.,limited has marched into abroad market for its mechanical seal principle .

2. We have an efficient sales team. They ensure close cooperation from start to delivery (and beyond) to ensure that the quality and timeliness of the project remains at the target level. Thanks to years of efforts, we have been awarded as "China Famous Exporter". This award demonstrates that we have strong manufacturing capacities and good manufacturing practices. We have a team of well qualified and trained staff. They are able to provide expert, impartial and friendly advice on projects, and carry out continuous improvement on both product quality and services. We have brought up a professional customer service team. They have the mindsets of paying attention to clients' concerns and solve their problems in a wholehearted way.

3. Innovation, excellence, and proximity serve as the compass for our actions. They shape a strong corporate culture that makes our vision a reality. Respect for customers is one of the values of our company. And we have succeeded in teamwork, collaboration, and diversity with our customers. Get more info! As a provider of social obligations, we see it as an obligation to effectively handle energy and resources and prevent environmental hazards in all of our regions. We take immense pride in providing the best service. We work hard to ensure that you are well taken care of when you choose us. Your satisfaction is our main priority and we strive to prove that every day. Get more info!

Custom rod end seals for reciprocating piston rod or piston single acting seal

rod end seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US