DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Custom oil seal manufacturer factory for aviation

- Since the establishment, Dms Seals has always been adhering to the service concept to serve every customer wholeheartedly. We receive acclaim from customers by providing thoughtful and caring services.

1. oil seal manufacturer shows excellent properties owing to adopting the materials of .

2. Our raw materials used in oil seal manufacturer is totally different from traditional ones.

3. Apart from the traditional style of oil seal manufacturer , has also added some new effect.

4. The body frame of oil seal manufacturer can be .

5. It runs well in an electromagnetic environment. It is able to function as intended in the presence of several electromagnetic phenomena.

6. Strong stability is one of its biggest selling points. Its stiles have been laminated to further enhance firmness and toughness.

7. The product operates reliably within its electromagnetic compatibility environment. It is less likely to generate any electromagnetic interference to other devices.

8. The product has a stable and constant chemical composition and physical properties which are determined by the internal structure.

9. The product is gentle for fragile and sensitive pool surface. It is specifically designed with soft cleaning function to protect the floor.

10. Customers say one of the reasons they like it so much is when they strike it lightly, it will ring with a clear bell-like sound which makes them delightful.

11. The product is often used in remote and hard-to-reach locations where the device needs to be self-powered.

12. The product is simple to use. It allows the operator to move throughout the working area quickly, accurately and safely.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

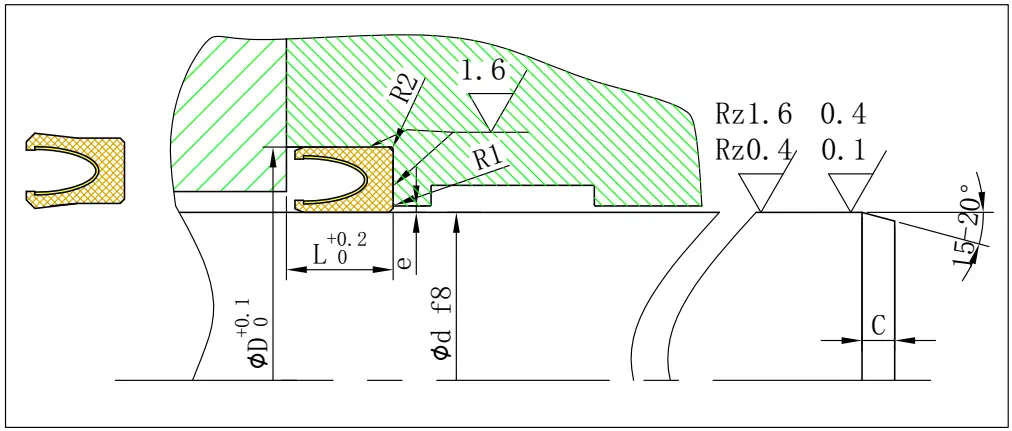

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is widely famous in creating beautiful oil seal manufacturer . Dms Seals Technology Co.,limited is a well-known company that specializes in exceptional delta mechanical seals . In all aspects of mechanical seal ring design and production, Dms Seals Technology Co.,limited has become a leader in the industry. While manufacturing and supplying quality spring energized seals at a reasonable price, Dms Seals Technology Co.,limited has earned a high level of customer trust. Dms Seals Technology Co.,limited is always committed to the manufacturing of high quality spring seals .

2. DMS Seal Manufacturer becomes increasingly more popular and famous because of its high-quality oil seal spring . Dms Seals Technology Co.,limited has attentive, dedicated and professional design team. In order to win the leading position in the mse seal market, DMS Seal Manufacturer invested a lot of money to strengthen the technical force. In order to be at the forefront of the mechanical seal standard industry, DMS Seal Manufacturer always insists on technological innovation. Our factory invests in high speed and automated equipment to increase efficiency.

3. Dms Seals Technology Co.,limited aims to stay ahead of the market. Contact us! DMS Seal Manufacturer staff helps company to win many customers for its high-end service. Contact us! In Dms Seals Technology Co.,limited, providing good service is always the key to seeking good development for company. Contact us! Dms Seals Technology Co.,limited holds the business idea of and hope to succeed together with our customers. Contact us!

Custom oil seal manufacturer factory for aviation

oil seal manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US