DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

compact rubber seal molding wholesale for larger piston clearance

1. Our professional designers can provide help in designing rubber seal molding . Seal we produced has applications in a wide range of fields

2. This product consumes little electricity and helps save on much energy costs due to its high efficiency. In this way, it will contribute to a reduction in operation costs. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

3. It meets the client’s requirement in every term of quality and durability. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

4. The product has been approved by creditable quality certificates. We have developed solutions of the sealing of special working condition

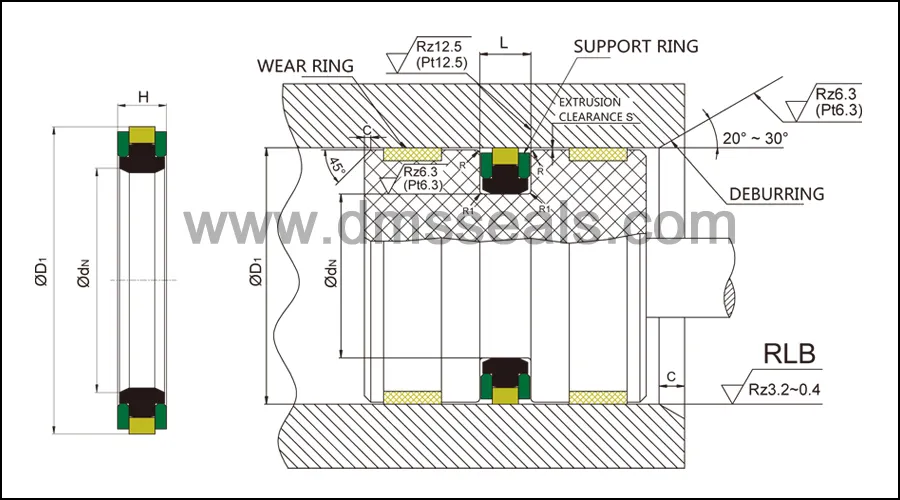

1. Installation Recommendation

2. Application and properties

Suitable for long stroke, a wide range of fluids and high temperature occasions. The application of heavy duty double acting piston sealing under high pressure conditions is excellent. Applicable to larger piston clearance , it has good leakage control, extrusion resistance and wear resistance in heavy duty and construction machinery cylinder piston sealing system. Good static sealing property, simple groove structure, larger extrusion clearances can be allowed, be able to work in dusty condition.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

50 - 350mm | 0 - 50MPa | -30℃ +100℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

Nominal Size of Packing, and Housing dimensions | L+0.2 | Order No. | ||

D1 | dN | H | ||

50 55 60 | 36 41 46 | 8.5 8.5 8.5 | 9 9 9 | SPGW50*36*8.5 SPGW55*41*8.5 SPGW60*46*8.5 |

63 65 70 | 48 50 55 | 10.5 10.5 10.5 | 11 11 11 | SPGW63*48*10.5 SPGW65*50*10.5 SPGW70*55*10.5 |

75 80 85 | 60 65 70 | 10.5 10.5 10.5 | 11 11 11 | SPGW75*60*10.5 SPGW80*65*10.5 SPGW85*70*10.5 |

90 95 100 | 75 80 85 | 10.5 10.5 12 | 11 11 12.5 | SPGW90*75*10.5 SPGW95*80*10.5 SPGW100*85*12 |

105 110 115 | 90 95 100 | 12 12 12 | 12.5 12.5 12.5 | SPGW105*90*12 SPGW110*95*12 SPGW115*100*12 |

120 125 130 | 105 102 107 | 12 15.5 15.5 | 12.5 16 16 | SPGW120*105*12 SPGW125*102*15.5 SPGW130*107*15.5 |

135 140 145 | 112 117 122 | 15.5 15.5 15.5 | 16 16 16 | SPGW135*112*15.5 SPGW140*117*15.5 SPGW145*122*15.5 |

150 155 160 | 127 132 137 | 15.5 15.5 15.5 | 16 16 16 | SPGW150*127*15.5 SPGW155*132*15.5 SPGW160*137*15.5 |

165 170 180 | 142 147 157 | 15.5 15.5 15.5 | 16 16 16 | SPGW165*142*15.5 SPGW170*147*15.5 SPGW180*157*15.5 |

185 190 200 | 162 167 177 | 15.5 15.5 15.5 | 16 16 16 | SPGW185*162*15.5 SPGW190*167*15.5 SPGW200*177*15.5 |

210 220 225 | 187 197 202 | 15.5 15.5 17 | 16 16 17.5 | SPGW210*187*15.5 SPGW220*197*15.5 SPGW225*202*15.5 |

230 240 250 | 207 217 222 | 17 17 17 | 17.5 17.5 17.5 | SPGW230*207*15.5 SPGW240*217*15.5 SPGW250*222*17 |

260 270 280 | 232 242 252 | 17 17 17 | 17.5 17.5 17.5 | SPGW260*232*17 SPGW270*242*17 SPGW280*252*17 |

300 320 350 | 272 292 322 | 17 17 17 | 17.5 17.5 17.5 | SPGW300*272*17 SPGW320*292*17 SPGW350*322*17 |

Company Features

1. Dms Seals Technology Co.,limited has been operating in a pragmatic manner since its inception. Our factory has a number of automated or semi-automated production lines capable of handling large production yield needs. These lines are fully flexible to gear different production adjustments.

2. Our workshop is located in a city where is a transportation well-developed metropolis in seaway, airway, and land. This advantageous location has enabled us to shorten the delivery time as well as transportation fees.

3. Our products and services combine traditional practices and modern techniques that are utilized by leading manufacturers around the world. Our business philosophy is based on the highest standards. We always strive to better understand the wants, needs, and expectations of our customers and to constantly exceed them.

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US