DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

compact hydraulic piston seals suppliers with nbr or fkm o ring for pneumatic equipment DMS Seal Manufacturer

1. DMS Seal Manufacturer hydraulic piston seals suppliers is well manufactured throughout the entire process. It has to go through complicated processes such as extraction, mixture, cutting, shaping, and final treatment.

2. DMS Seal Manufacturer hydraulic piston seals suppliers is produced under up-to-date technology. From the textile fiber screening to the quality inspection stage, nanotechnology, supercritical fluid extraction technology, and plasma technology are applied.

3. The manufacture of DMS Seal Manufacturer hydraulic piston seals suppliers is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

4. The quality of DMS Seal Manufacturer piston seals is guaranteed at the very beginning. Exhaustive quality control testing is done for all its materials to ensure that any inferior component would be replaced long before production begins.

5. DMS Seal Manufacturer piston seals is well processed at the preliminary stage. During the ore extraction, explosives are used to break up the ore material which is then taken away to be refined.

6. This product is eco-friendly and generates no waste. Some parts used in it are recycled materials, maximizing the use of useful and available materials.

7. The rebound ability of the product shall be noticed. It's just like a platform allows the foot to land and bounce back effortlessly and quickly to reduce energy loss.

8. The product has the appropriate hardness which has a direct relation with the types of bonds connecting the carbon atoms in its mineral structures.

9. Its structure is designed for maximum efficiency and easiest ongoing maintenance for the lowest total cost in both installation and everyday use.

10. It ensures a good reflectivity. Its actual reflective surface has been structured down to a microscopic level in order to reflect the projected image directly into the viewer’s field of vision.

11. The product is becoming more famous over the years due to its huge economic benefits.

12. This product is much more popular in end user's market.

13. Most costumers consider the product has huge market potential and worth of trust.

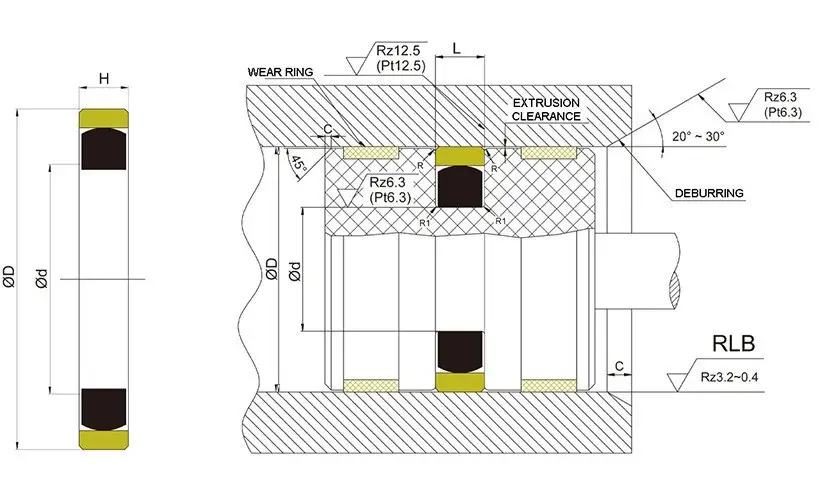

Bore Diameter | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | |||

D H8 | d h8 | L1+0.2 | R1 | 16MPa | 26MPa | 32MPa | 40MPa |

55.0-149.9 | D-10.0 | 10.0 | 0.4 | 0.60 | 0.50 | 0.40 | 0.40 |

150.0-244.9 | D-12.5 | 12.5 | 0.4 | 0.75 | 0.65 | 0.55 | 0.50 |

245.0-500.0 | D-15.0 | 15.0 | 0.8 | 0.75 | 0.65 | 0.55 | 0.50 |

500.1-760.0 | D-17.5 | 17.5 | 1.2 | 0.75 | 0.65 | 0.55 | 0.50 |

760.1-999.9 | D-20.0 | 20.0 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

≧1000 | D-20.0 | 20.5 | 1.2 | 0.80 | 0.70 | 0.60 | 0.55 |

Application and properties

Applied to the hydraulic cylinder of heavy machinery and metallurgical equipment. Pressure resistance and corrosion resistance are strong, good thermal conductivity,structure anti-distortion, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+100℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. |

D H8 | d h8 | L+0.2 | |

55 | 40 | 10 | GSF-W55*40*10 |

80 | 60 | 10 | GSF-W80*60*10 |

110 | 90 | 10 | GSF-W110*90*10 |

130 | 110 | 10 | GSF-W130*110*10 |

160 | 135 | 12.5 | GSF-W160*135*12.5 |

180 | 155 | 12.5 | GSF-W180*155*12.5 |

200 | 175 | 12.5 | GSF-W200*175*12.5 |

215 | 190 | 12.5 | GSF-W215*190*12.5 |

230 | 205 | 12.5 | GSF-W230*205*12.5 |

Company Features

1. Dms Seals Technology Co.,limited is a highly competitive modern enterprise manufacturing piston seals . The R&D and production capability of o-ring seal is highly recognized by industry people. With strong sense of responsibility, DMS Seal Manufacturer always pursues perfection during the process of manufacturing hydraulic piston seals . Dms Seals Technology Co.,limited has been focusing on piston seals for years with unique and exquisite craftsmanship.

2. Dms Seals Technology Co.,limited takes a leading role in terms of technology competency. The leaders of DMS Seal Manufacturer always pay closer to the quality of piston seals . DMS Seal Manufacturer attaches great importance to the quality of piston seals .

3. Following the guideline of hydraulic piston seals suppliers , DMS Seal Manufacturer strongly believes it will advance better in the near future. Get price! piston seals is the gene of DMS Seal Manufacturer which is the driving force to continue to develop its business. Get price! DMS Seal Manufacturer determines to be the leading hydraulic piston seals manufacturer in accordance with the spirit of piston seals . Get price! There is no doubt that Dms Seals Technology Co.,limited will do everything possible to better serve our customers. Get price!

compact hydraulic piston seals suppliers with nbr or fkm o ring for pneumatic equipment DMS Seal Manufacturer

piston seals

Type:spg 、 Type1:gsd

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US