DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

combined piston seals glyd ring for light and medium hydraulic systems

- Dms Seals has built a service system that meets the needs of consumers. It has won wide acclaim and support from customers.

1. DMS Seal Manufacturer piston seals has to go through diverse tests. These tests are strictly conducted in terms of stress points, support points, yield points, wear resistance, toughness, friction force, etc.

2. The design of DMS Seal Manufacturer piston seals is conducted under CAD technologies. The CAD technologies illustrate the exact locations of electric components and the arrange of circuits of the product.

3. DMS Seal Manufacturer rubber piston seals will be carefully packed before shipment. Insert it into a protective plastic cover by hand or by robot.

4. The quality of DMS Seal Manufacturer piston seals is accredited. It is checked in our testing laboratory in terms of numerous chemical and optical characteristics.

5. DMS Seal Manufacturer rubber piston seals has undergone a series of quality tests such as light transmission capability and light collecting ability, which is crucial for lighting effects.

6. The product is characterized by high performance and good durability.

7. Its quality is ensured with the help of a very strict inspection system.

8. The product is strictly tested by the quality team on a series of parameters ensuring its quality.

9. This product is versatile and widely used in various fields.

10. The product is widely praised by users for its good characteristics and has high market application potential.

11. The product has high practical value and commercial value and is now widely used in the market.

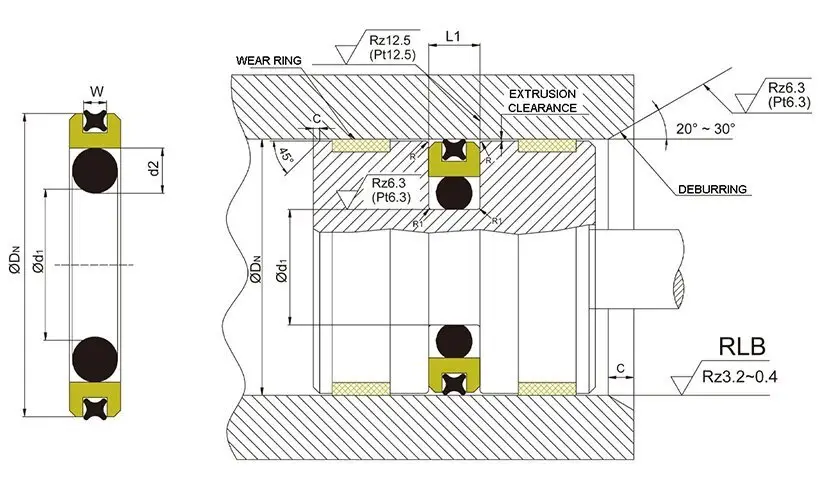

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Light Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

15 - 39.9 | 40 - 79.9 | DN - 11.0 | 4.2 | 1.0 | 0.25 | 0.15 | 0.10 | 3.53 | 1.78 |

40 - 79.9 | 80 - 132.9 | DN - 15.5 | 6.3 | 1.3 | 0.3 | 020 | 0.15 | 5.33 | 1.78 |

80 - 132.9 | 133 - 252.9 | DN - 21.0 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

133 - 252.9 | -- | DN - 24.5 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

253 - 462.9 | -- | DN - 28.0 | 9.5 | 2.5 | 0.45 | 0.30 | 0.25 | 8.40 | 3.53 |

463 - 700 | -- | DN - 35.0 | 11.5 | 3.0 | 0.55 | 0.40 | 0.35 | 10.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Recommended for double-acting pistons as piston-type energy storage, supporting cylinder and positional cylinder. Double safety with low friction and high elasticity, good dynamic and static sealing performance, larger extrusion clearances can be allowed, at the same time with the function of holding pressure, less leakage in the hydraulic cylinder. Simple groove, small installation space, excellent sliding performance, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-40MPa | -30℃+200℃ | 2 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

70 | 59 | 4.2 | DAQ70*59*4.2 | 56.74*3.53 |

80 | 64.5 | 6.3 | DAQ80*64.5*6.3 | 62.87*5.33 |

85 | 64 | 8.1 | DAQ85*64*8.1 | 63*7.0 |

95 | 79.5 | 6.3 | DAQ95*79.5*6.3 | 78.74*5.33 |

100 | 79 | 8.1 | DAQ100*79*8.1 | 78*7.0 |

110 | 94.5 | 6.3 | DAQ110*94.5*6.3 | 91.44*5.33 |

115 | 94 | 8.1 | DAQ115*94*8.1 | 93*7.0 |

125 | 109.5 | 6.3 | DAQ125*109.5*6.3 | 107.32*5.33 |

130 | 109 | 8.1 | DAQ130*109*8.1 | 108*7.0 |

150 | 129 | 8.1 | DAQ150*129*8.1 | 126.37*7.0 |

180 | 159 | 8.1 | DAQ180*159*8.1 | 158.12*7.0 |

210 | 189 | 8.1 | DAQ210*189*8.1 | 183.52*7.0 |

240 | 219 | 8.1 | DAQ240*219*8.1 | 215.27*7.0 |

Company Features

1. Dms Seals Technology Co.,limited engages in manufacturing piston seals with stable quality. In order to offer not only the highest rubber piston seals but also the most professional hydraulic piston seals suppliers , DMS Seal Manufacturer employs staff who are in high demand. Dms Seals Technology Co.,limited is gradually taking the leading trend in the trade of o-ring seal. Dms Seals Technology Co.,limited has been devoted to R&D and production of hydraulic piston seals for many years.

2. We have an engaged R&D team who is always working hard on nonstop development and innovation. Their deep knowledge and expertise enable them to supply a whole set of product services to our clients. The company has established a strong R&D team. They are equipped with industry knowledge and experience. This enables them to offer professional advice on product custom or innovation. The modern workshop is equipped with sophisticated production facilities. These facilities have been certified under safety and quality standards. This laid a solid base for us to provide clients with high-quality products. Our Research & Development department plays a central role in achieving our business objectives. Their high level of expertise and experience are put to good use in shaping the development process. Our business has been successfully expanding to many regions and countries. So far, we have earned a relatively large foreign market share, and the sales volumes are estimated to increase in the coming years.

3. Trustworthy, Heartwarming, Energetic! is the motto that was born from our efforts to determine what makes us special. We will continue to keep these words firmly placed in our hearts. Our business is devoted to sustainability. We're working proactively to reach zero waste to landfill by buying state-of-the-art equipment for recycling the blank waste out of manufacturing. We'll stick to the high standards of integrity business behavior. We deny any kinds of practices that harm our brand name. We will firmly refuse any sharing of clients' privacy and order information. Our company is getting leaner and greener faster than ever. We made efforts in sustainable manufacturing that focuses on waste prevention, environmental impacts, worker health, and safety. Our company is socially responsible for our performance. For example, our overall goal is to achieve the lowest potential CO2 emission.

combined piston seals glyd ring for light and medium hydraulic systems

piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US