DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

carbon fiber filled spring energized seals parts for reciprocating piston rod or piston single acting seal

- Dms Seals has a comprehensive service system covering from pre-sales to after-sales. We are able to provide one-stop and thoughtful services for consumers.

-

v s

1. DMS Seal Manufacturer spring energized seals is designed in a completely innovative manner, crossing boundaries of furniture and architecture. The design is carried out by experienced designers who tend to create vivid, multifunctional, and space-saving furniture pieces which can also be easily transformed into something else.

2. The production processes of DMS Seal Manufacturer oil seal spring are as followed. They are fabric cutting, printing, sewing, thread trimming, washing, ironing, folding, and packing.

3. The fabrics of DMS Seal Manufacturer oil seal spring have been rigorously tested before used. They are tested using various methods such as combustion, staining, or shrinking.

4. An internal team or a third-party team is hired to determine whether the product meets the standards.

5. The product has an exceptional and stable quality thanks to the implementation of the scientific quality management system.

6. Internal quality control team makes sure the comprehensive functionality.

7. The product is highly acclaimed for its high quality and excellent performance and versatility.

8. The product meets the highest level of quality and safety.

9. The product has found an increasingly wide utilization in the fields.

10. We control quality of spring energized seals from raw material to every stage of production.

11. The actual application prospects of this product are broad.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

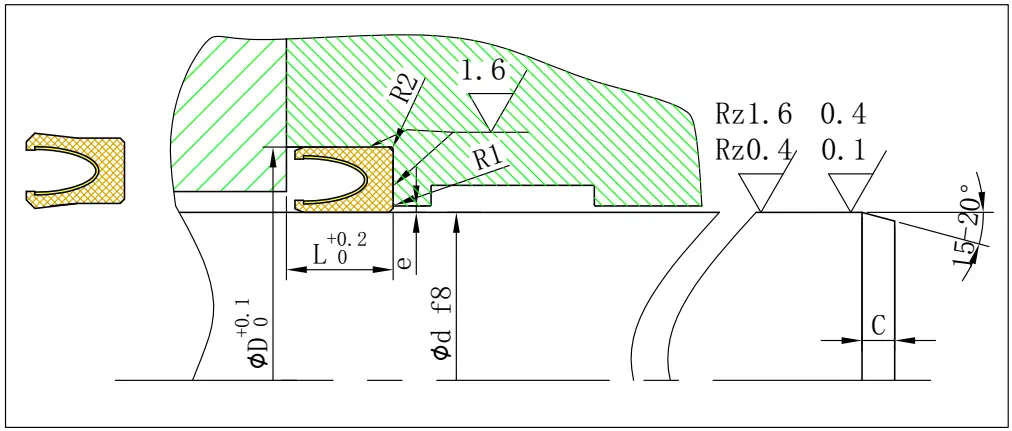

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. DMS Seal Manufacturer has made great achievements in spring energized seals industry. DMS Seal Manufacturer is a technically advanced supplier. DMS Seal Manufacturer has been among the best in the oil seal manufacturer industry for many years. Dms Seals Technology Co.,limited specializes in the manufacture and supply of spring seals . Dms Seals Technology Co.,limited leads in the development and production of advanced technologies for spring energized seals .

2. Staff working in Dms Seals Technology Co.,limited are all well-trained. Almost all technician talent for the industry of spring energized seals work in our Dms Seals Technology Co.,limited. The quality of our spring energized seals still keeps unsurpassed in China.

3. The DMS Seal Manufacturer desire is to win the global market and become a oil seal spring manufacturer. Check it! Dms Seals Technology Co.,limited seek commonality in R&D while preserving differences with customers. Check it! We want to be the leading spring loaded seal supplier in the industry. Check it! Our ultimate goal is to be one of the leading spring energized seals suppliers. Check it! Dms Seals Technology Co.,limited takes pride in its unique culture and great organizational soul, and we will not let you down. Check it!

carbon fiber filled spring energized seals parts for reciprocating piston rod or piston single acting seal

spring energized seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US