DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

carbon fiber filled spring energized seals parts for aviation

1. Ideas for the design of DMS Seal Manufacturer spring loaded seal are presented under high technologies. The product's shapes, colors, dimension, and matching with space will be presented by 3D visuals and 2D layout drawings.

2. Quality and conformity inspection for DMS Seal Manufacturer spring energized seals will be conducted during the production process. Workmanship, measurements, and safety inspection are essential checking parts in every production stage.

3. DMS Seal Manufacturer spring loaded seal goes through important manufacturing processes. They may be divided into several parts: the provision of working drawings, the selection&machining of raw materials, staining, spraying, and polishing.

4. The fabrics performance of DMS Seal Manufacturer spring energized seals has been analyzed. It has been assessed in terms of breathability, moisture management, heat management, softness, stiffness, roughness, and smoothness.

5. Essential quality tests for DMS Seal Manufacturer spring energized seals have been carried out. These tests cover the aspects of seam strength, stitch density, colorfastness, and crocking.

6. This product meets customers' expectations for functionality, reliability and durability.

7. The product is inspected to industry standards to ensure it is free of defects.

8. The product is durable and has a long service life.

9. The inspection of the product is paid 100% attention. From the materials to the finished products, each step of inspection is strictly conducted and followed.

10. These products are widely marketed meeting the specific requirements of customers.

11. This product is over and above our rival's product, and yet we're able to sell it at the same price.

12. It has gained abundant good reviews from its users.

13. The product has many good characteristics and caters to the varied demands of our clients, showing a wide use in the future.

14. The product adapts to market need and is widely used at home and abroad.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

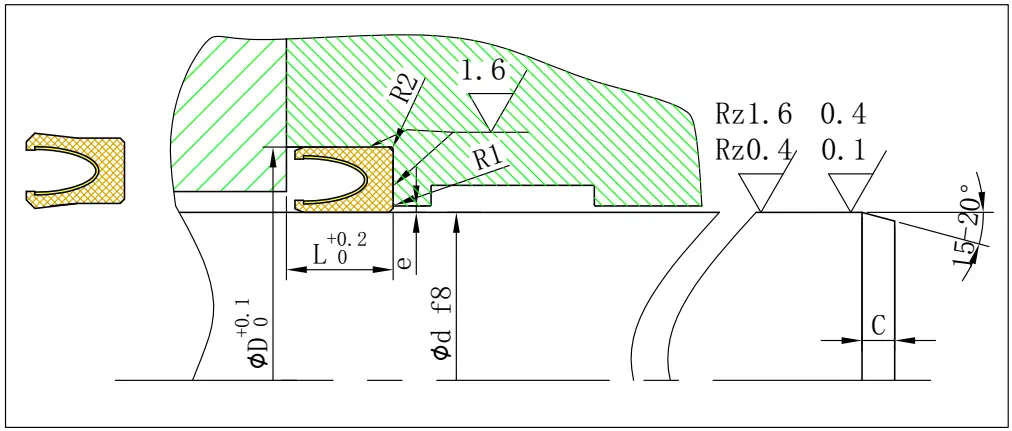

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. With a good reputation as a trusted manufacturer of spring loaded seal , Dms Seals Technology Co.,limited has been widely accepted in the industry. Dms Seals Technology Co.,limited acts as an important role in providing high-quality spring energized seals . We specialize in designing, manufacturing, and marketing in the industry. Dms Seals Technology Co.,limited provides customers with a complete spring energized seals services including development, design, production, and quality control. Dms Seals Technology Co.,limited is one of the most dependable manufacturers of oil seal spring and has been highly appraised for its extensive expertise in designing and manufacturing.

2. DMS Seal Manufacturer owns fantastic technology to produce spring seals . The efforts of improving the quality of oil seal manufacturer has been paid. To increase its competence in the market, DMS Seal Manufacturer largely invested into optimizing the technology to produce spring energized seals . Modern technologies for spring loaded seal are introduced into Dms Seals Technology Co.,limited.

3. We want to become even more a brand that people love - A future-proof and high-quality company with strong premium consumer and business relations. We are not just in the business of revolutionary product development, we’re in the business of revolutionary partner development. Get price! We work closely with our customers to find the perfect combination of products and services to achieve a comprehensive balance between performance and price effectiveness. We always persist in the policy of "Professional, Whole-hearted, High-quality." We hope to work with more brand owners from worldwide to develop and manufacture different creative products. Get price!

carbon fiber filled spring energized seals parts for aviation

spring energized seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US