DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

bronze hydraulic rod seals supplier to high and low speed

- Dms Seals can provide professional and practical services based on customer demand.

1. DMS Seal Manufacturer hydraulic rod seals has undergone a series of tests such as tensile strength tests, tear tests, H-Drawing tests, compression tests including set up of its stop force.

2. DMS Seal Manufacturer piston rod seal is produced under a complete sophisticated production process, including forging and pressing, mechanical processing, cleaning, and surface treating.

3. DMS Seal Manufacturer piston rod seal is designed by adopting the concept of space-saving without compromising on function or style. Meanwhile, it meets the requirement of international aesthetical standard in the sanitary ware industry.

4. The quality control of DMS Seal Manufacturer piston rod seal is strictly conducted. Stringent measures on raw material extraction and regular testing procedures have been carried out to cater to building structural elements.

5. Before production, the electrode materials of DMS Seal Manufacturer piston rod seal are carefully handled to prevent them from coming into contact with each other. Because contamination between the anode and cathode materials will ruin the battery.

6. This product is wear and tear resistant. The table-board and panel are made of wear-resistant materials which protect the surface of the product from the damage of heavy use.

7. The product has a fine tenacity. It can withstand the influence of exterior force such as incision, peening, bending, and pulling.

8. The product can offer water that is clean and harmless. Its activated charcoal, with maximized number of pores, has largely widens its absorption surface to remove more pollutant molecules.

9. There is no crosstalk problem in the PCB of the product. During the arrangement of wires, the signal line, power line, and the ground wire are arranged within the appropriate distance without interfering each other.

10. piston rod seal developed by Dms Seals Technology Co.,limited might could revolutionize hydraulic rod seals industry.

11. Dms Seals Technology Co.,limited has great work efficiency and all its production tasks can be completed in a quality and quantity manner.

12. Dms Seals Technology Co.,limited presently has opened many overseas markets.

13. Samples of hydraulic rod seals can be provided for our customers' checking and confirmation before mass production.

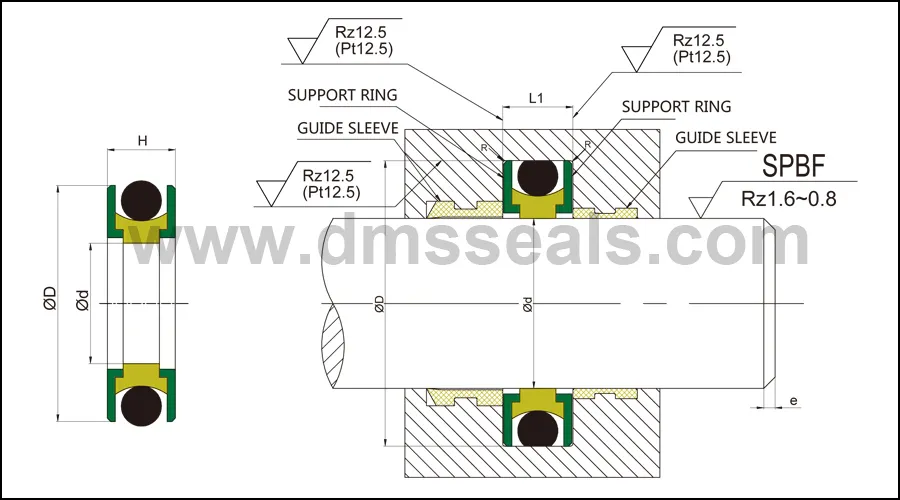

1. Installation Recommendation

2. Installation Sizes

d e8 | D H9 | L D10 | H |

22-39 | d+7.2 | 4.0 | 3.5 |

40-79 | d+10.0 | 5.0 | 4.5 |

80-100 | d+13.8 | 7.5 | 7.0 |

d+20.0 | 10.0 | 9.5 | |

>250-600 | d+30.0 | 15.0 | 14.5 |

>600 | d+40.0 | 20.0 | 19.5 |

3. Application and properties

L-Ring support and guide to ensure a tight sealing environment. Easy installation, wear resistance, anti extrusion, low friction, non stick slip phenomenon.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

L-Ring: POM / PA

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 45MPa | -30℃ +100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

D1 H9 | H | L D10 | e | Order No. | |

22 25 28 | 29.2 32.2 35.2 | 3.5 3.5 3.5 | 4 4 4 | 6 6 6 | RDI22*29.2*3.5 RDI25*32.2*3.5 RDI28*35.2*3.5 |

30 32 35 | 37.2 39.2 42.2 | 3.5 3.5 3.5 | 4 4 4 | 6 6 6 | RDI30*37.2*3.5 RDI32*39.2*3.5 RDI35*42.2*3.5 |

36 40 42 | 43.2 50 52 | 3.5 4.5 4.5 | 4 5 5 | 6 6 6 | RDI36*43.2*3.5 RDI40*50*4.5 RDI42*52*4.5 |

45 50 55 | 55 60 65 | 4.5 4.5 4.5 | 5 5 5 | 6 6 6 | RDI45*55*4.5 RDI50*60*4.5 RDI55*65*4.5 |

56 60 63 | 66 70 73 | 4.5 4.5 4.5 | 5 5 7.5 | 6 7 7 | RDI56*66*4.5 RDI60*70*4.5 RDI63*73*4.5 |

65 70 72 | 75 80 82 | 4.5 4.5 4.5 | 7.5 7.5 7.5 | 7 7 7 | RDI65*75*4.5 RDI70*80*4.5 RDI72*82*4.5 |

75 80 85 | 85 93.8 98.8 | 4.5 7.0 7.0 | 7.5 7.5 7.5 | 7 7 7 | RDI75*85*4.5 RDI80*93.8*7.0 RDI85*98.8*7.0 |

90 95 100 | 103.8 108.8 113.8 | 7.0 7.0 7.0 | 7.5 7.5 7.5 | 7 7 7 | RDI90*103.8*7.0 RDI95*108.8*7.0 RDI100*113.8*7.0 |

105 110 115 | 125 130 135 | 9.5 9.5 9.5 | 10 10 10 | 10 10 10 | RDI105*125*9.5 RDI110*130*9.5 RDI115*135*9.5 |

120 125 130 | 140 145 150 | 9.5 9.5 9.5 | 10 10 10 | 10 10 10 | RDI120*140*9.5 RDI125*145*9.5 RDI130*150*9.5 |

Company Features

1. Dms Seals Technology Co.,limited is a state-owned backbone enterprise in hydraulic rod seals industry. Dms Seals Technology Co.,limited now has many research and development institutions, nurturing a number of well-known brands such as DMS Seal Manufacturer. Dms Seals Technology Co.,limited is a O Ring Manufacturers manufacturer that integrates piston rod seal R& D, manufacture and sales. Dms Seals Technology Co.,limited is a global leader in o-ring seal.

2. We have made our products sell all over the world in the USA, Europe, and Asia now. Our customers are from enterprise, government, or even some very famous brands. This is further proof of our capability. The factory is lawfully granted with a production certificate. This means that what the factory produces are safe and non-harmful to people. The factory will do its best to implement national industrial policies to protect the rights and interests of the majority of consumers to the utmost extent. Our staff all have a background related to the industry. They have passed through professional education and training. They have a good employment history and field experience.

3. We are honest and straightforward. We say what needs to be said and hold ourselves accountable. We earn the trust and confidence of others. Our integrity defines and leads us. Ask! We are finding ways to partner with customers to design solutions. We have been focusing on establishing close partnerships with our clients so as to come up with the most ideal products. Ask! Dms Seals Technology Co.,limited is committed to the global development of rod seal catalogue industry. Ask!

bronze hydraulic rod seals supplier to high and low speed

hydraulic rod seals

Type:spn 、 Type1:gsi

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US