DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

bronze filled shaft seals for pumps o ring

- provides customers with a full range of services to meet the individual needs of different customers.

1. Safety check for DMS Seal Manufacturer is carried out by the QC team during the production. It will be checked for its electrical safety includes input voltage, amperage, anti-surge-current capability, etc.

2. A wide range of tests for DMS Seal Manufacturer has been conducted. It has been tested in some aspects such as circuit board, plugs, voltage, frequency, etc.

3. DMS Seal Manufacturer meet safety obligations and related standards. Its construction and maintenance strictly meet the safety requirements within the Electricity Safety Regulations.

4. Strict quality inspection on DMS Seal Manufacturer will be conducted. It is required to pass the quality standards such as RoHS, REACH, MSDS in the battery industry.

5. Products must be inspected by our inspection system to ensure that the quality meets industry requirements.

6. To meet customer's expectation and the industry standard, the product has to be subjected to strict quality inspection before shipment.

7. As we have established a good quality management system to prevent any possible defects, the quality of products is guaranteed.

8. Our strict quality management system ensures that our products are always in the best quality.

9. Advanced machines in DMS Seal Manufacturer allows us to produce mass production.

10. As the leading shaft seals for pumps manufacture, DMS Seal Manufacturer is specialized in producing high quality products.

11. Thanks to our popular shaft seals for pumps , DMS Seal Manufacturer has developed many western partners.

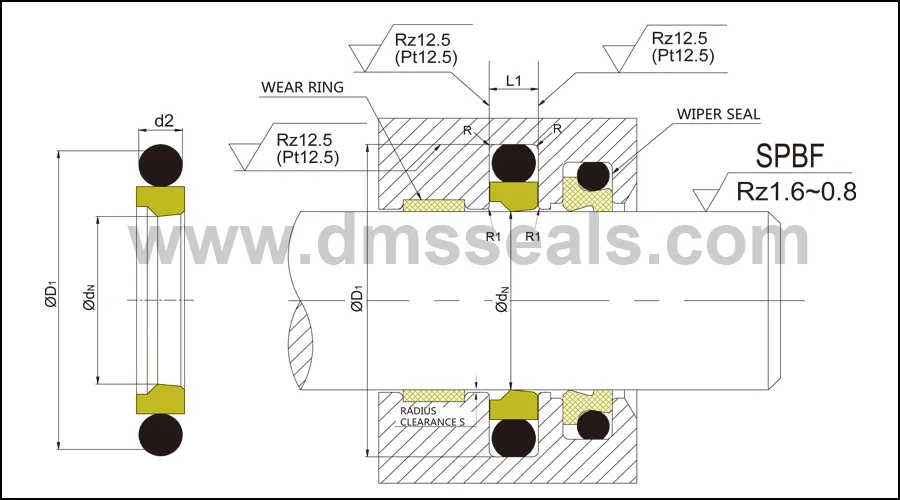

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation.

Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

4 5 6 | 8.9 9.9 10.9 | 2.2 2.2 2.2 | GSJ4*8.9*2.2 GSJ5*9.9*2.2 GSJ6*10.9*2.2 | 5.28*1.78 6.75*1.78 7.65*1.78 |

8 8 10 | 12.9 15.3 14.9 | 2.2 3.2 2.2 | GSJ8*12.9*2.2 GSJ8*15.3*3.2 GSJ10*14.9*2.2 | 9.25*1.78 10.77*2.62 11.8*1.78 |

10 12 12 | 17.3 16.9 19.3 | 3.2 2.2 3.2 | GSJ10*17.3*3.2 GSJ12*16.9*2.2 GSJ12*19.3*3.2 | 12.37*2.62 13.3*1.78 13.94*2.62 |

14 14 15 | 18.9 21.3 19.9 | 2.2 3.2 2.2 | GSJ14*18.9*2.2 GSJ14*21.3*3.2 GSJ15*19.9*2.2 | 15.6*1.78 15.54*2.62 16.67*1.78 |

15 16 16 | 22.3 20.9 23.3 | 3.2 2.2 3.2 | GSJ15*22.3*3.2 GSJ16*20.9*2.2 GSJ16*23.3*3.2 | 17.12*2.62 17.17*1.78 18.72*2.62 |

18 18 19 | 22.9 25.3 29.7 | 2.2 3.2 4.2 | GSJ18*22.9*2.2 GSJ18*25.3*3.2 GSJ19*29.7*4.2 | 18.77*1.78 20.29*2.62 23.39*3.53 |

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited takes the lead in product quality. Dms Seals Technology Co.,limited is a front-runner in the shaft seals for pumps industry for the considerate customer service and exceptional products. Dms Seals Technology Co.,limited is globally competitive in the rubber seal strip suppliers marketplace. Dms Seals Technology Co.,limited is a reliable expert in producing seal manufacturing process . Dms Seals Technology Co.,limited is widely recognized as a dependable manufacturer of sunny oil seal manufacturer .

2. Our design team is comprised of proficient and knowledgeable talents. They have specialized skills in computer-aided design and allows us to provide the most attractive design for our customers. We have expanded our selling channels in different countries. They mainly include Europe, South America, Middle East, and Southeast Asia. Our products, in these markets, sell like hotcakes. At our manufacturing factory in China, we have a highly professional QC team. They ensure the highest level of product consistency and comply fully with industry guidelines.

3. In every detail of the work, Dms Seals Technology Co.,limited follows the highest ethical standards. Ask! Our core value is a strong teamwork spirit. We encourage not only internal teamwork, but also the cooperation across boundaries. By this way, we work better with our partners to meet their requirements which in return helps our company grow. Ask! We strive to guarantee client satisfaction. No matter how big order it is that customers place with us, rest assured that we will deliver impeccable results. Ask!

bronze filled shaft seals for pumps o ring

shaft seals for pumps

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US