DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

best mechanical seal ring wholesale

1. Innovative design team: DMS Seal Manufacturer is elaborately designed by an innovative design team. This team has learned the industry know-how and are equipped with the latest design ideas in the industry. To reduce costs with high-efficiency work is the DMS's purpose

2. People will find that it has a wide range of applications in our daily life. They can find it exists in fields such as telecommunication, navigation, national defenses, etc. Our products mainly include rod seals, piston seals, scraper seals, rotary seals, rubber seal products and spring seals

3. This product can stand up to variable temperatures. Its shapes and texture will be not easily affected by different temperatures thanks to the natural properties of its materials. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

4. This product is not afraid of liquids. Thanks to its self-cleaning surface, it will not stain from spills, such as coffee, tea, wine, or fruit juice. DMS Seal manufacturer is a technology enterprise which specialized in the R&D and production of seals

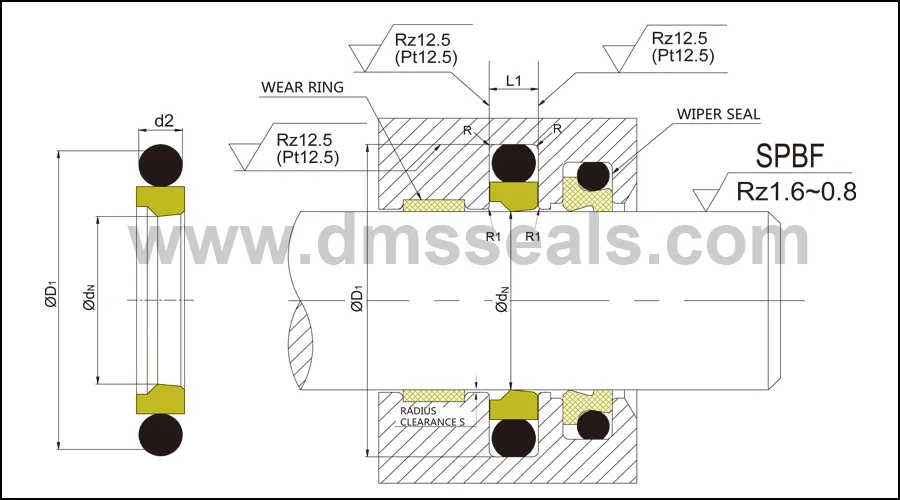

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation.

Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

4 5 6 | 8.9 9.9 10.9 | 2.2 2.2 2.2 | GSJ4*8.9*2.2 GSJ5*9.9*2.2 GSJ6*10.9*2.2 | 5.28*1.78 6.75*1.78 7.65*1.78 |

8 8 10 | 12.9 15.3 14.9 | 2.2 3.2 2.2 | GSJ8*12.9*2.2 GSJ8*15.3*3.2 GSJ10*14.9*2.2 | 9.25*1.78 10.77*2.62 11.8*1.78 |

10 12 12 | 17.3 16.9 19.3 | 3.2 2.2 3.2 | GSJ10*17.3*3.2 GSJ12*16.9*2.2 GSJ12*19.3*3.2 | 12.37*2.62 13.3*1.78 13.94*2.62 |

14 14 15 | 18.9 21.3 19.9 | 2.2 3.2 2.2 | GSJ14*18.9*2.2 GSJ14*21.3*3.2 GSJ15*19.9*2.2 | 15.6*1.78 15.54*2.62 16.67*1.78 |

15 16 16 | 22.3 20.9 23.3 | 3.2 2.2 3.2 | GSJ15*22.3*3.2 GSJ16*20.9*2.2 GSJ16*23.3*3.2 | 17.12*2.62 17.17*1.78 18.72*2.62 |

18 18 19 | 22.9 25.3 29.7 | 2.2 3.2 4.2 | GSJ18*22.9*2.2 GSJ18*25.3*3.2 GSJ19*29.7*4.2 | 18.77*1.78 20.29*2.62 23.39*3.53 |

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited is an honest enterprise which specializes in mechanical seal ring . We have employed a professional sales team. Their in-depth knowledge of the market allows us to build the appropriate sales strategy to maximize the product’s success.

2. The workshop is equipped with world-class integration equipment, including automatic assembly machines and testing equipment. These machines can firmly support bulk order and guarantee the net production per day.

3. We have boasted a dedicated sales & marketing team. They have good communication and excellent project coordination skills, which allows them to service customers in a satisfactory manner. DMS Seal Manufacturer combines our deep industry knowledge, expertise and innovative thinking to fuel your business growth. Get price!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US