DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

best dripless shaft seal manufacturers for construction machinery

1. We conduct process inspection in DMS Seal Manufacturer manufacture. Common assessments, such as colorfastness to washing and rubbing, fiber strength, fiber structure, and chemical reagents are carried out by the QC team. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

2. Dms Seals Technology Co.,limited appears to have secured competitive advantage in best dripless shaft seal markets. DMS o-ring seal has advanced machines and equipment for its production

3. High dimensional accuracy is the prominent point of the product. Advanced cutting tools and techniques are applied to ensure its dimension precision. Seal we produced has applications in a wide range of fields

4. It is hypoallergenic and resistant to dust mites. Allergens like dust mites and pollen cannot get in the densely weaved strands of this product. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

5. With its fabric's breathability and high functionality, this product is the ideal solution for warm sleep, especially since it provides excellent heat control and high moisture-absorbing level. We have developed solutions of the sealing of special working condition

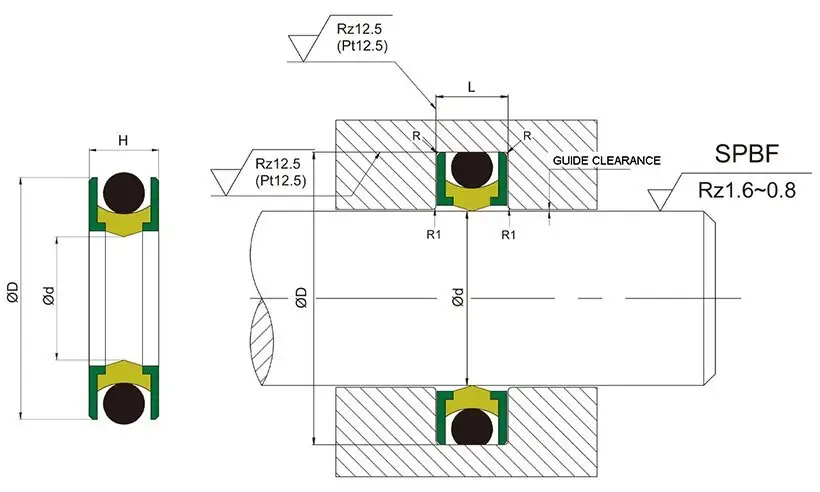

Rod Diameter | Groove Diameter | Seal Width | Groove Width | Guide Clearance S max | |

d e8 | D H9 | H | L | 0-10MPa | 15-36MPa |

50-79 | d+10.0 | 4.5 | 5.0 | 0.40-0.30 | 0.30-0.25 |

80-109 | d+13.8 | 7.0 | 7.5 | 0.45-0.35 | 0.35-0.30 |

110-299 | d+20.0 | 9.5 | 10.0 | 0.55-0.45 | 0.45-0.35 |

300-600 | d+24.0 | 12.5 | 13.0 | 0.60-0.55 | 0.55-0.45 |

Application and properties

Applicable to construction machinery, construction machinery and automotive equipment and other industrial fields. Consisting of a sealing ring, a O-Ring and two retaining rings, the sealing surface profile is specially designed to accommodate high pressure and low speed, the design of the back of the seal ring increases the contact surface and prevents rotation with the rod or shaft. Low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-36MPa | -36℃+100℃ | 0.5 m/s | hydraulic oil, flame retardant liquid, water and others |

d e8 | D H9 | H | L | e | Order No. |

50 | 60 | 4.5 | 5 | 7 | OI50*60*4.5 |

65 | 75 | 4.5 | 5 | 7 | OI65*75*4.5 |

80 | 93.8 | 7.0 | 7.5 | 7 | OI80*93.8*7 |

95 | 108.8 | 7.0 | 7.5 | 7 | OI95*108.8*7 |

115 | 135 | 9.5 | 10 | 10 | OI115*135*9.5 |

130 | 150 | 9.5 | 10 | 10 | OI130*150*9.5 |

160 | 180 | 9.5 | 10 | 10 | OI160*180*9.5 |

190 | 210 | 9.5 | 10 | 10 | OI190*210*9.5 |

225 | 245 | 9.5 | 10 | 10 | OI225*245*9.5 |

Company Features

1. Through the technology, best dripless shaft seal is produced to be of high quality.

2. Dms Seals Technology Co.,limited is prepared to present the best service and high pressure oil seals suppliers for every single client. Welcome to visit our factory!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US