DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

4 inch hydraulic cylinder seal kit glyd ring for light and medium hydraulic systems

- With a professional service team, Dms Seals is able to provide all-round and professional services which are suitable for customers according to their different needs.

1. The glaze workmanship of DMS Seal Manufacturer includes overglaze decoration, in glaze decoration, and under-glaze decoration. Especially the under-glaze decoration, which directly determines the pattern quality, is processed by experienced workers.

2. The management systems and quality control of DMS Seal Manufacturer mainly rely on our highly calibrated testing scales, computerized testing reports, state-of-the-art hardness testers.

3. The materials or components used in DMS Seal Manufacturer are strictly selected by QC team. The selected materials or components have to be tested under professional devices or machines to check their reliability.

4. In order to meet the standards of the heatsink industry, DMS Seal Manufacturer has to go through a strict inspection process conducted by precise inspection equipment.

5. It comes with good breathability. It allows moisture vapor to pass through it, which is an essential contributing property to thermal and physiological comfort.

6. This product has good color retention. The dye molecules unite tightly with the fibers, enabling them not to shed off from the fibers.

7. This product has a proper SAG factor ratio of near 4, which is much better than the much lesser 2 - 3 ratio of other mattresses.

8. The product is allergy free. Any allergens dyestuffs or chemical sensitizers such as alkylphenol ethoxylates are all eliminated during its production with the help of hypoallergenic chemical agents.

9. With its compact design, it takes up very small space. People can flexibly put it in any unoccupied place.

10. The use of this product helps meet the need for social production. It not only improves productivity but also reduces labor costs.

11. The product, featuring high automation and efficiency, can cut the number for unskilled workers, which helps reduces labor costs.

12. People can trust that the product is able to offer a solid barrier against intruders, enhancing the security level for the buildings.

13. The product helps clean the dirt under the pool or any particles on the shore of the pool, which can reduce the risk of slipping.

Application and properties

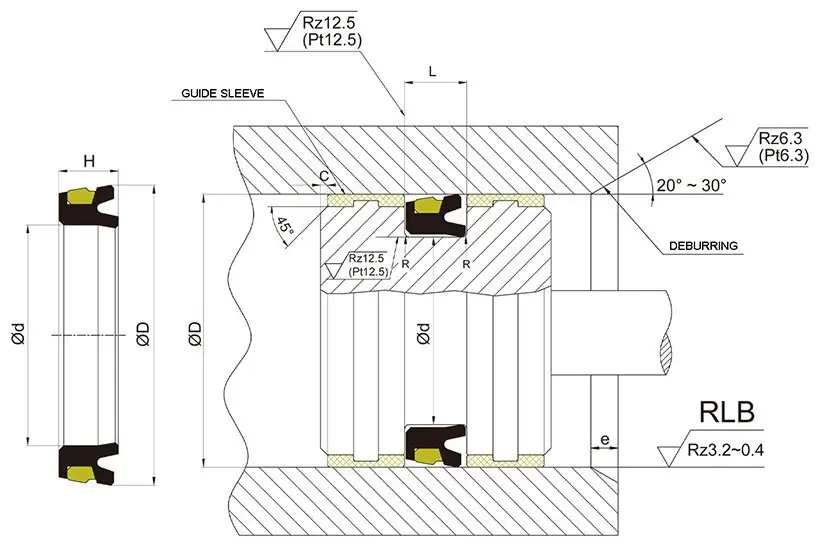

Apply to the hydraulic cylinder of piston sealing, generally used in conjunction with the guide sleeve. The seal ring and piston conforming to be a symmetric section to achieve the sealing performance. The Non-standard Y-ring has the function of sealing and provides the elastic force to the sealing ring and compensates for the abrasion. Very high pressure stability under pressure and harsh conditions, high wear resistance, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

Y-Ring: NBR / PU

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L+0.2 | e | Order No. |

40 | 32 | 7 | 7.5 | 6 | DDA40*32*7.5 |

45 | 37 | 7 | 7.5 | 6 | DDA45*37*7.5 |

55 | 45 | 7 | 7.5 | 6 | DDA55*45*7.5 |

63 | 48 | 12 | 13 | 6 | DDA63*48*13 |

70 | 55 | 12 | 13 | 6 | DDA70*55*13 |

80 | 65 | 12 | 13 | 6 | DDA80*65*13 |

90 | 75 | 12 | 13 | 7 | DDA90*75*13 |

105 | 90 | 12 | 13 | 7 | DDA105*90*13 |

120 | 105 | 12 | 13 | 7 | DDA120*105*13 |

140 | 120 | 12 | 13 | 7 | DDA140*120*13 |

160 | 140 | 12 | 13 | 10 | DDA160*140*13 |

180 | 160 | 16 | 17 | 10 | DDA180*160*17 |

200 | 180 | 16 | 17 | 10 | DDA200*180*17 |

Company Features

1. By introducing advanced production lines, Dms Seals Technology Co.,limited mainly produces high-quality . Dms Seals Technology Co.,limited is the most progressive manufacturer of in China. We focus on steady growth since establishment. Dms Seals Technology Co.,limited is an outstanding resource for budget, schedule, and quality. We have the experience and resources to meet the most demanding specifications on .

2. DMS Seal Manufacturer constantly optimizes 4 inch hydraulic cylinder seal kit production technologies. The production technology has been constantly optimized by DMS Seal Manufacturer. DMS Seal Manufacturer has attained the worldwide level in important technical areas like R&D, layout, construction and manufacturing. Dms Seals Technology Co.,limited introduced advanced technology of hydraulic seal kits suppliers .

3. To ensure timely delivery, we use an efficient project management system. It allows us to invite all our managers and assign tasks to them within a given time frame. Inquire! We have set commitments and objectives to use and manage resources sustainably by operating more efficiently, responding to climate change, reducing production loss and waste, and caring for the water. We achieve sustainable development by reducing production waste. We have diverted our manufacturing and post-consumer waste solutions from landfill and waste valorization by incineration to higher value beneficial uses like recycling and upcycling.

4 inch hydraulic cylinder seal kit glyd ring for light and medium hydraulic systems

4 inch hydraulic cylinder seal kit

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US